Introduction

The Cummins KTA38 and KTA50 diesel engines are built for demanding industrial, marine, and power generation applications. To ensure peak performance, reliability, and longevity, these engines require routine scheduled maintenance at regular intervals.

Following Cummins’ recommended maintenance intervals helps prevent unexpected failures, maximizes fuel efficiency, and extends engine life. This guide outlines detailed maintenance procedures at 250-hour, 1,500-hour, and 6,000-hour intervals, providing step-by-step instructions for keeping your KTA38 and KTA50 running smoothly.

Parts Catalog for KTA38 Cummins Marine and Industrial Engines

Parts Catalog for KTA50 Cummins Marine and Industrial Engines

Scheduled Maintenance Intervals for Cummins KTA38 and KTA50

Cummins recommends progressive maintenance at different operating hours, ensuring all major components receive the necessary inspections, replacements, and servicing.

Key Maintenance Intervals:

- 250 Hours or 6 Months – Routine checks and fluid changes.

- 1,500 Hours or 1 Year – Intermediate maintenance, fuel system service, and valve adjustments.

- 6,000 Hours or 2 Years – Comprehensive inspection, component replacement, and overhaul work.

Each interval builds upon the previous one, ensuring all engine components remain in optimal working condition.

250 Hours or 6 Months Maintenance for Cummins KTA38 and KTA50

At 250-hour or 6-month intervals, routine servicing focuses on fluid replacements, fastener inspections, and component cleaning. These tasks help prevent early wear, improve efficiency, and reduce operational risks.

1. Change Engine Oil and Filters

Why It’s Important:

- Engine oil lubricates and protects internal components.

- Dirty oil leads to sludge buildup, reducing engine efficiency.

- Old oil increases wear on bearings, pistons, and valve train components.

How to Perform the Oil Change:

- Warm up the engine for a few minutes to loosen contaminants.

- Place an oil drain pan under the engine.

- Remove the oil drain plug and allow the oil to drain completely.

- Replace the oil filter using a Cummins-approved replacement.

- Refill with the recommended oil type (SAE 15W-40 for most conditions).

- Check the oil level using the dipstick and adjust as needed.

Recommended Oil Capacity:

- Cummins KTA38: Approx. 28 gallons (106 liters)

- Cummins KTA50: Approx. 34 gallons (129 liters)

2. Inspect Cooling System Hoses and Belts

Why It’s Important:

- Cracked hoses and loose belts can cause overheating.

- A leaking cooling system can lead to catastrophic engine failure.

How to Perform the Inspection:

- Check all coolant hoses for cracks, bulges, and leaks.

- Inspect clamps and connections for tightness.

- Check belt tension – Press on the belt, and it should deflect slightly but not be loose.

- Replace any damaged hoses or worn-out belts immediately.

Fresh Water Pump & Related Components for Cummins KTA38 Engine

Fresh Water Pump & Related Components for Cummins KTA50 Engine

Marine Raw Water Pump & Related Components for Cummins KTA38 Engine

Marine Raw Water Pump & Related Components for Cummins KTA50 Engine

3. Test Coolant for Chemical Balance and Contamination

Why It’s Important:

- Coolant prevents overheating and corrosion.

- Contaminated coolant leads to scaling and blockages.

How to Test Coolant:

- Use a coolant test strip to check pH balance and nitrate levels.

- Inspect for oil or fuel contamination (milky or dark coolant indicates contamination).

- If coolant is discolored, acidic, or contaminated, flush and replace it.

4. Check and Tighten Fasteners and Mounting Bolts

Why It’s Important:

- Loose bolts can lead to excessive vibrations and component failure.

- Securing all fasteners prevents leaks and misalignment.

How to Perform the Check:

- Inspect engine mounts, accessory brackets, and cylinder head bolts.

- Use a torque wrench to tighten fasteners to Cummins specifications.

Common Torque Specifications:

- Cylinder Head Bolts: 125-135 ft-lbs

- Main Bearing Cap Bolts: 220-240 ft-lbs

- Connecting Rod Bolts: 90-110 ft-lbs

Marine Raw Water Pump & Related Components for Cummins KTA38 Engine

Marine Raw Water Pump & Related Components for Cummins KTA50 Engine

5. Inspect and Clean Air Intake System and Pre-Cleaners

Why It’s Important:

- A clean air filter ensures proper combustion and fuel efficiency.

- Clogged filters can lead to turbocharger damage.

How to Perform the Inspection:

- Remove the air filter and inspect it for dust and debris.

- If the filter is clogged or damaged, replace it with a Cummins-approved filter.

- Clean the pre-cleaner and check the intake piping for obstructions.

Turbo & Related Components for Cummins KTA38 Engine

Turbo & Related Components for Cummins KTA50 Engine

1,500 Hours or 1 Year Maintenance for Cummins KTA38 and KTA50

At 1,500 hours or 1 year, the maintenance schedule includes fuel system servicing, cooling system flushing, valve adjustments, and exhaust inspections.

1. Replace Fuel Filters to Ensure Optimal Fuel Delivery

Why It’s Important:

- Clogged fuel filters reduce fuel pressure, leading to power loss.

- Regular replacement prevents injector damage.

How to Replace Fuel Filters:

- Turn off the engine and relieve fuel pressure.

- Remove the primary and secondary fuel filters.

- Fill the new filters with clean diesel fuel.

- Install the new filters and bleed the fuel system to remove air pockets.

Fuel Filter & Related Components for Cummins KTA38 Engine

Fuel Filter & Related Components for Cummins KTA50 Engine

2. Flush and Replace Engine Coolant

Why It’s Important:

- Old coolant loses its anti-corrosion properties.

- Scaling and rust can block coolant flow.

How to Perform the Flush:

- Drain the old coolant completely.

- Refill with distilled water and a cleaning solution, run the engine, and then drain.

- Refill with Cummins-approved coolant (50/50 mix with distilled water).

Fresh Water Pump & Related Components for Cummins KTA38 Engine

Fresh Water Pump & Related Components for Cummins KTA50 Engine

Marine Water Pump For Cummins Marine Engine KTA38 and KTA50 engines

Marine Raw Water Pump & Related Components for Cummins KTA38 Engine

Marine Raw Water Pump & Related Components for Cummins KTA50 Engine

3. Inspect and Clean Fuel Injectors

Why It’s Important:

- Dirty injectors cause misfires, smoke, and power loss.

- Carbon buildup affects fuel atomization.

How to Perform the Cleaning:

- Remove fuel injectors and inspect for deposits.

- Clean using ultrasonic fuel injector cleaner.

- Replace any worn-out injectors.

Injector & Related Components for Cummins KTA38 Engine

Injector & Related Components for Cummins KTA50 Engine

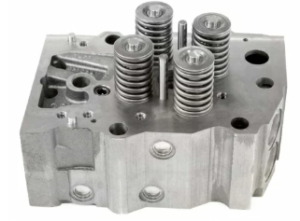

4. Adjust Valve Clearances for Proper Combustion

Why It’s Important:

- Incorrect valve clearance affects engine performance.

- Loose or tight valves lead to power loss and excess wear.

How to Perform the Adjustment:

- Remove the valve cover and check clearances using a feeler gauge.

- Adjust each valve to the manufacturer’s specifications.

6,000 Hours or 2 Years Maintenance for Cummins KTA38 and KTA50

At 6,000 hours or 2 years, the entire engine system undergoes a detailed inspection, and major components may require replacement.

1. Inspect and Rebuild Turbochargers if Necessary

- Check for shaft play, oil leaks, and unusual noises.

- Rebuild or replace if performance loss or damage is detected.

Turbo & Related Components for Cummins KTA38 Engine

Turbo & Related Components for Cummins KTA50 Engine

2. Replace Piston Rings and Cylinder Liners if Wear is Detected

- Inspect for oil consumption, blow-by gases, and compression loss.

- Replace worn rings and liners to restore engine efficiency.

Piston Kit & Related Components for Cummins KTA38 Engine

Piston Kit & Related Components for Cummins KTA50 Engine

3. Check and Test Fuel Pump Calibration

- Use fuel pump calibration tools to verify accurate fuel delivery.

- Adjust timing and fuel rate for optimal combustion and efficiency.

Fuel Pump & Related Components for Cummins KTA38 Engine

Fuel Pump & Related Components for Cummins KTA50 Engine

4. Replace Main Bearings and Connecting Rod Bearings if Needed

- Inspect bearings for excessive wear or metal shavings.

- Replace to prevent engine failure due to bearing damage.

Crankshaft & Related Components for Cummins KTA38 Engine

Crankshaft & Related Components for Cummins KTA50 Engine

5. Conduct a Full Cooling System Inspection, Including Radiator Flushing

- Remove radiator and flush all coolant passages.

- Inspect water pump and thermostat for wear.

Fresh Water Pump & Related Components for Cummins KTA38 Engine

Fresh Water Pump & Related Components for Cummins KTA50 Engine

Marine Water Pump For Cummins Marine Engine KTA38 and KTA50 engines

Marine Raw Water Pump & Related Components for Cummins KTA38 Engine

Marine Raw Water Pump & Related Components for Cummins KTA50 Engine

Conclusion

By following this scheduled maintenance plan, Cummins KTA38 and KTA50 engines will operate efficiently and reliably for thousands of hours.

Key Takeaways:

✔ Change oil and filters every 250 hours.

✔ Perform fuel system maintenance and valve adjustments at 1,500 hours.

✔ Overhaul turbochargers, piston rings, and cooling systems every 6,000 hours.

For high-quality Cummins aftermarket parts, visit Diesel Pro Power, ensuring your KTA38 and KTA50 engines stay in top condition.

Parts Catalog for KTA38 Cummins Marine and Industrial Engines

Parts Catalog for KTA50 Cummins Marine and Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588