Rebuilding the Cummins 6BT with Diesel Pro Parts – A Visit to Imperial Diesel Service

Inside the Shop: A Rebuilt Cummins 6BT from Imperial Diesel Service

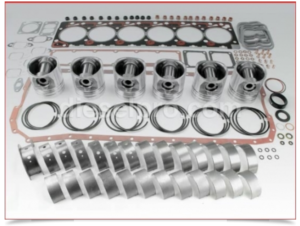

During a recent visit to Imperial Diesel Service, we had the chance to capture footage of a beautifully rebuilt Cummins 6BT engine — assembled using premium aftermarket parts from DieselPro.com. The video, now live on our Diesel Pro YouTube Channel, highlights the craftsmanship and care that go into every 6BT rebuild when quality parts meet expert hands.

The Cummins 6BT: Still a Legend

The Cummins 6BT (5.9L) is a legend in the diesel engine world — known for its simplicity, durability, and widespread use across trucks, marine vessels, construction equipment, and agricultural machinery. These engines are built to last, but when it’s time for an overhaul, you want parts that perform just as well (if not better) than OEM — and that’s where Diesel Pro comes in.

Why Mechanics Choose DieselPro.com for 6BT Rebuilds

Reputable diesel shops like Imperial Diesel Service trust Diesel Pro Power for a reason. Our Cummins 6BT rebuild kits and individual components are built to exacting standards, ready to handle extreme workloads.

We offer:

-

Full rebuild kits with pistons, rings, bearings, liners, and seals

-

Fresh water pumps, injectors, turbochargers, and more

-

Fast shipping and real diesel engine support

Whether you’re rebuilding for marine, industrial, or trucking use — we’ve got your back.

Watch the Rebuild in Action

Check out the video from our visit to Imperial Diesel Service and see the quality of a 6BT rebuild done right using Diesel Pro parts. It’s a great example of what happens when premium parts meet professional service.

Why Buy Your Cummins 6BT Parts From Diesel Pro Power?

Over 40,000 Satisfied Customers Worldwide

From independent marine operators to large-scale industrial power companies, we’ve built a customer base based on trust, speed, and support. With thousands of five-star reviews and repeat customers, we’ve earned our place as a global leader in diesel engine support.

Fast, Worldwide Shipping

We ship within 24 hours—often same-day. We can reach:

-

Shipyards and marinas

-

Offshore oil platforms

-

Island power plants

-

Agricultural irrigation stations

-

Construction equipment hubs

Intuitive Online Ordering

Our site is:

-

Accurate – Cross-referenced with OEM part numbers

-

Simple – No diesel knowledge required to navigate

-

Fast – Optimized for both desktop and mobile

Secure and Private

We implement the latest encryption and data protection standards. Order with confidence knowing your information is safe.

World-Class Customer Service

Our diesel parts team is standing by to help you:

-

Identify the correct parts

-

Confirm CPL compatibility

-

Advise on installation and repair

-

Track international shipments

Call, email, or chat with a real expert—not a call center.

Where the Cummins 6BT Shines – Applications We Support

The Cummins 6BT is a workhorse across countless marine and industrial installations:

Marine Applications

-

Fishing vessels and trawlers – Heavy-duty power under full load

-

Towboats and utility craft – Reliable auxiliary and propulsion systems

-

Onboard marine gensets – Powering lights, refrigeration, and hydraulics

-

Bilge and fire pumps – Emergency and mission-critical functions

-

Harbor patrol and inspection boats

Industrial Applications

-

Diesel generator sets – Prime and backup power systems

-

Irrigation and dewatering – Engine-driven pump systems

-

Construction site compressors

-

Hydraulic drive units – For cranes, lifts, and presses

-

Stationary processing equipment – Logging, mining, and concrete batching

Cummins 6BT Engine Specifications

Specification

Detail

Configuration

Inline 6-cylinder, 4-stroke diesel

Displacement

5.9 liters (359 cubic inches)

Bore x Stroke

4.02 in x 4.72 in (102 mm x 120 mm)

Aspiration

Turbocharged (non-aftercooled in base 6BT versions)

Fuel System

Mechanical direct injection (Bosch VE or inline pump)

Compression Ratio

17.5:1

Horsepower Range

120–180 HP @ 2,500–2,800 RPM

Peak Torque

400–440 lb-ft @ 1,600–1,800 RPM

Oil Capacity

Approx. 15–16 quarts (14–15 liters)

Cooling System

Liquid-cooled, gear- or belt-driven water pump

Dry Weight

1,050–1,100 lbs (476–499 kg)

Flywheel Housing

SAE #2 or #3

Emissions Tier

Pre-Tier 1, Non-electronic

Valvetrain

OHV with 2 valves per cylinder

Lifespan (Before Overhaul)

10,000–20,000+ hours with proper care

The 6BT’s turbocharged configuration offers a major leap in performance over naturally aspirated versions while retaining mechanical simplicity. In many cases, it provides medium-duty power in applications where larger engines might have once been required.

Applications of the Cummins 6BT Engine

The 6BT engine is trusted by operators across the globe because it delivers excellent fuel efficiency, long service intervals, and consistent performance under heavy load. The 6BT is commonly used in off-highway machinery, generator systems, marine auxiliaries, agricultural equipment, and more. Its enduring popularity is rooted in its ability to perform in environments where electronic engines may struggle or fail due to complexity or parts availability.

1. Marine Auxiliary and Generator Use

The Cummins 6BT is widely used in marine auxiliary systems as well as onboard and dockside generator sets, offering reliable power in both stationary and mobile marine platforms.

Marine Use Cases:

-

Marine gensets (60–100 kW range)

-

Hydraulic power units (winches, cranes, stabilizers)

-

Diesel-powered refrigeration compressors

-

Desalination or bilge pump engines

-

Fire suppression system pumps

-

Fuel transfer systems

The turbocharger improves performance at low RPM—essential for maintaining load under constant-duty applications. Its mechanical simplicity and non-electronic fuel system reduce the risk of failure from humidity, salt air, and vibration, especially in coastal or offshore conditions.

2. Power Generation Systems

One of the most common industrial applications of the 6BT is in stationary and mobile diesel generator sets. Its consistent RPM operation, low fuel consumption, and rugged mechanical design make it ideal for both standby and prime power roles.

Generator Applications:

-

Prime power for remote mining camps and oilfield trailers

-

Emergency backup systems for buildings and hospitals

-

Telecom tower gensets in off-grid areas

-

Trailer-mounted utility power solutions

-

Industrial process power and wastewater pump stations

The 6BT’s turbocharged performance provides fast recovery under load, which is critical for preventing voltage drops in sensitive power applications.

3. Construction & Utility Equipment

The 6BT is also found in a wide range of off-road construction and utility machinery, where torque, uptime, and fuel efficiency are mission-critical.

Common Applications:

-

Wheel loaders and backhoes

-

Trenchers, compactors, and pavers

-

Aerial lifts and boom trucks

-

Skid-mounted compressors and pump skids

-

Rail maintenance machinery

-

Airport ground support vehicles

Thanks to its compact package and service accessibility, the 6BT is an excellent match for equipment that must operate in harsh environments with limited shop access.

4. Agricultural Machinery

The 6BT’s robust torque output and ability to deliver constant power at fixed RPM make it a go-to engine for many agricultural power units.

Agricultural Use Cases:

-

Diesel irrigation pumps

-

Stationary power for feed mills or dryers

-

Auger and conveyor drives

-

Tractor repower engines

-

Generator sets for barns and farm facilities

Farmers prefer the 6BT for its cold-start ability, low maintenance, and long runtime, especially during planting or harvest seasons.

5. Oilfield and Heavy Utility Applications

The oil and gas industry relies on the 6BT for auxiliary support across rigs, trailers, and standalone utility units. Its simplicity and consistent torque output are ideal for long-duration operations far from service centers.

Oilfield Uses:

-

Trailer-mounted generators and compressors

-

Mud pump and fuel pump drives

-

Hydraulic power units for casing and pipe handling

-

Mobile fluid transfer systems

-

Light tower engines and refrigeration support

In these sectors, engines must operate around the clock with minimal interruption. The 6BT offers a balance of power and durability that makes it a favorite for oilfield service companies worldwide.

6. Global Export and Repower Markets

The 6BT’s mechanical design and emissions flexibility make it extremely attractive in international markets where Tier 4 Final engines are cost-prohibitive or impractical.

Global Applications:

-

Power generation systems in Africa, Asia, and Latin America

-

Agricultural and construction equipment repowering

-

Skid-mount utility engines for global NGO and disaster response projects

-

Marine auxiliary and genset installations in export boats

-

Industrial retrofits in legacy OEM machinery

Its shared parts lineage with 6B and 6BTA engines ensures global parts availability, while rebuild kits and long service life reduce total cost of ownership.

Key Advantages of the Cummins 6BT Engine

-

Turbocharged Performance – Increased horsepower and torque without compromising engine life.

-

Mechanical Simplicity – No ECUs or sensors—easier to troubleshoot, rebuild, and maintain.

-

Fuel Efficiency – Excellent consumption rates at mid-RPM under constant or load-variable duty.

-

Flexible Integration – Available in various flywheel housing and PTO configurations.

-

Rugged Design – Cast iron block, high-strength crankshaft, and gear-driven accessories.

-

Cold Weather Operation – Known for excellent starting in sub-zero temperatures.

-

Global Support – A massive aftermarket and service ecosystem ensures parts are available worldwide.

-

Rebuildability – Known to exceed 20,000 hours in properly maintained applications.

Conclusion

The Cummins 6BT engine is one of the most trusted diesel engines in the global aftermarket, offering the perfect blend of power, durability, and mechanical dependability. Whether you’re operating in marine, industrial, agricultural, or off-highway settings, the 6BT delivers consistent results with minimal electronics and low overhead.

Its turbocharged design gives it the extra performance edge over naturally aspirated counterparts, while its mechanical fuel system keeps it resilient in extreme or remote environments. For fleets looking to reduce downtime, simplify maintenance, or support legacy equipment, the 6BT remains one of the best diesel engine platforms available.

Additional Resources For The Cummins 6BT

Cummins 6BT 5.9L Turbo: Reliable Replacement for Marine Engines

Guide To Buying A Cummins 6BT Overhaul Kit

A Step-by-Step Guide to Installing a Cummins 6BT Sea Water Pump

Parts For Your Cummins 6BT 5.9 Engine

Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

FAQ: Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

Introduction – Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Understanding Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

General Maintenance Requirements for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Oil and Lubrication Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cooling System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Fuel System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Air Intake and Turbocharger Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cylinder Head and Valve Adjustment for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Electrical System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Exhaust System and Emissions Control for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Common Problems and Troubleshooting Guide for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Major Overhaul and Rebuild Considerations for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Storage and Long-Term Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Recommended Aftermarket Parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Conclusion: Ensuring Long-Term Reliability for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

-

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588