The Cummins B Series engines are renowned for their durability, reliability, and long service life. However, even the most well-maintained engines will eventually require a major overhaul or rebuild due to wear and tear, loss of compression, or internal damage.

A properly executed rebuild can restore your Cummins 6B, 6BT, 6BTA, 4B, 4BT, or 4BTA engine to like-new condition, improving performance, fuel efficiency, and reliability.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

This guide covers:

✔ When to consider an engine overhaul based on mileage, symptoms, and condition.

✔ Key components to replace during a rebuild to ensure long-term performance.

✔ Choosing the right rebuild kit (in-frame vs. overhaul kits).

✔ A step-by-step guide to performing a basic engine rebuild.

When to Consider an Engine Overhaul

A major engine overhaul is required when internal components experience excessive wear, leading to power loss, excessive smoke, poor fuel economy, or increased oil consumption.

1. Common Signs That an Overhaul is Needed

✔ Low Compression: Hard starts, power loss, and excessive blow-by.

✔ High Oil Consumption: Burning oil, blue exhaust smoke, or frequent oil top-offs.

✔ Loss of Power and Performance: Engine struggles under load or has weak acceleration.

✔ Excessive Smoke from Exhaust: Black (fuel overuse), white (coolant leak), or blue (burning oil) smoke.

✔ Knocking or Excessive Engine Noise: Worn pistons, bearings, or connecting rods.

✔ Frequent Overheating: Poor cooling system efficiency, worn head gasket, or cracked cylinder head.

✔ If your engine shows multiple signs of failure, a full rebuild may be necessary to restore performance.

Key Components to Replace During an Engine Rebuild

A complete engine overhaul involves replacing worn-out components to restore the engine to its original factory condition. Below is a list of critical components that should be inspected and replaced during a rebuild.

1. Cylinder Head and Valve Train Components

✔ Cylinder Head: Inspect for cracks, warping, and valve seat damage.

✔ Valves, Guides, and Seats: Replace worn valves and guides to restore compression.

✔ Head Gasket: Always install a new high-quality head gasket to prevent leaks.

✔ Valve Springs and Rocker Arms: Ensure proper valve movement and reduce engine noise.

✔ A properly rebuilt cylinder head improves compression, efficiency, and fuel combustion.

Cylinder Head & Related Components for Cummins 6B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 6BTA Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4B Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BT Marine and Industrial Engines

Cylinder Head & Related Components for Cummins 4BTA Marine and Industrial Engines

2. Pistons, Rings, and Liners

✔ Pistons and Rings: Worn pistons reduce compression and cause blow-by.

✔ Cylinder Liners: Inspect for scoring or wear—replace if out of spec.

✔ Piston Wrist Pins: Ensure smooth movement and replace if loose.

✔ New pistons and rings restore compression and eliminate oil burning.

Piston Kit & Related Components for Cummins 4B Marine and Industrial Engines

Piston Kit& Related Components for Cummins 4BT Marine and Industrial Engines

Piston Kit& Related Components for Cummins 4BTA Marine and Industrial Engines

Piston Kit& Related Components for Cummins 6B Marine and Industrial Engines

Piston Kit & Related Components for Cummins 6BT Marine and Industrial Engines

Piston Kit & Related Components for Cummins 6BTA Marine and Industrial Engines

3. Bearings and Crankshaft Components

✔ Main Bearings and Rod Bearings: Replace for smoother operation and oil pressure consistency.

✔ Crankshaft and Connecting Rods: Check for wear and regrind if necessary.

✔ Thrust Bearings: Ensure proper crankshaft end-play.

✔ Replacing bearings ensures smooth engine operation and extends lifespan.

Crankshaft & Related Components for Cummins 4B Marine and Industrial Engines

Crankshaft & Related Components for Cummins 4BT Marine and Industrial Engines

Crankshaft & Related Components for Cummins 4BTA Marine and Industrial Engines

Crankshaft & Related Components for Cummins 6B Marine and Industrial Engines

Crankshaft & Related Components for Cummins 6BT Marine and Industrial Engines

Crankshaft & Related Components for Cummins 6BTA Marine and Industrial Engines

4. Fuel System Components

✔ Fuel Injectors: Clean or replace for even fuel distribution.

✔ Fuel Pump: Check pressure output and replace if weak.

✔ Lift Pump: Essential for proper fuel delivery—replace if malfunctioning.

✔ A fully functional fuel system ensures efficient combustion and maximum power output.

Fuel Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fuel Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Injector & Related Components for Cummins 4B Marine & Industrial Engines

Injector & Related Components for Cummins 4BT Marine & Industrial Engines

Injector & Related Components for Cummins 4BTA Marine & Industrial Engines

Injector & Related Components for Cummins 6B Marine & Industrial Engines

Injector & Related Components for Cummins 6BT Marine & Industrial Engines

Injector & Related Components for Cummins 6BTA Marine & Industrial Engines

5. Cooling and Lubrication System Components

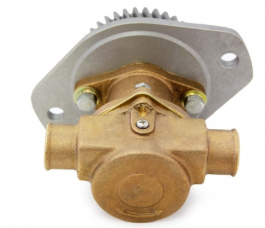

✔ Water Pump: Prevent overheating by installing a new water pump.

✔ Oil Pump: A worn oil pump leads to low oil pressure—replace if necessary.

✔ Thermostat and Radiator Hoses: Prevent overheating and coolant leaks.

✔ Cooling and lubrication system health is essential for preventing overheating and premature wear.

Fresh Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Fresh Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 4BTA Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6B Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BT Marine & Industrial Engines

Marine Raw Water Pump & Related Components for Cummins 6BTA Marine & Industrial Engines

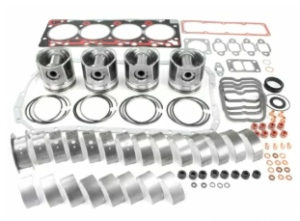

Choosing the Right Rebuild Kit (Overhaul vs. In-Frame Kits)

When rebuilding a Cummins B Series engine, you must choose between an in-frame rebuild kit or a complete overhaul kit.

1. What is an In-Frame Rebuild Kit?

An in-frame rebuild is performed without removing the engine from the vehicle or vessel.

✔ Includes:

- Pistons, rings, and cylinder liners

- Main and rod bearings

- Gaskets and seals

✔ Best for:

- Engines with no major block or crankshaft damage

- Extending engine life without full disassembly

2. What is an Overhaul (Out-of-Frame) Rebuild Kit?

An overhaul rebuild involves removing the engine from the vehicle or vessel for a complete tear-down and restoration.

✔ Includes:

- All in-frame components PLUS:

- Cylinder head rebuild components

- Camshaft and lifters

- Oil pump, water pump

- Turbocharger (if applicable)

✔ Best for:

- Engines with severe wear, internal damage, or high hours

- Restoring engine to like-new condition

✔ For a complete engine refresh, an overhaul kit is the best option.

Step-by-Step Guide to a Basic Rebuild Process

A proper rebuild requires precision, attention to detail, and the right tools and components. Below is a step-by-step guide to performing a basic in-frame or overhaul rebuild.

Step 1: Engine Disassembly

✔ Drain all fluids (oil, coolant, and fuel).

✔ Remove the cylinder head, exposing pistons and valves.

✔ Disconnect fuel injectors and pump for cleaning or replacement.

✔ Remove pistons and liners – Inspect for wear and scoring.

✔ Remove crankshaft and bearings – Check for out-of-spec tolerances.

✔ Keep all components organized and labeled for reassembly.

Step 2: Inspect and Clean Components

✔ Use a micro

meter to check piston and crankshaft tolerances.

✔ Inspect the cylinder head for cracks, warping, and worn-out valves.

✔ Measure bearing clearances to determine if crankshaft regrinding is needed.

✔ Thoroughly clean all engine components to remove carbon deposits and debris.

✔ Replacing worn components ensures a reliable rebuild with maximum longevity.

Step 3: Install New Components

✔ Install new pistons, rings, and cylinder liners using assembly lube.

✔ Torque bearings to factory specifications using a calibrated torque wrench.

✔ Reassemble fuel injectors and pump, ensuring proper calibration.

✔ Install a new head gasket and torque cylinder head bolts in the correct sequence.

✔ Precision installation is key to a long-lasting rebuild.

Step 4: Reassemble and Test

✔ Reinstall engine components in reverse order of disassembly.

✔ Check valve lash and timing settings to ensure proper operation.

✔ Fill with fresh oil and coolant, and prime the oil system.

✔ Perform an initial startup and break-in process to seat new components properly.

✔ A successful rebuild restores the engine to full power and efficiency.

Break-In Procedure for a Rebuilt Cummins B Series Engine

After rebuilding, proper engine break-in is essential for seating piston rings, bearings, and other moving parts.

✔ First 50 Hours:

- Avoid idling for extended periods.

- Gradually increase engine load.

✔ After 100 Hours:

- Change oil and filters to remove metal shavings.

- Perform a compression test to verify cylinder seal integrity.

✔ Following a proper break-in process extends engine life and improves efficiency.

Final Thoughts

A properly executed rebuild restores Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA engines to like-new performance, ensuring maximum reliability and efficiency. By following recommended rebuild procedures, selecting high-quality components, and performing a proper break-in, you can:

✔ Extend engine life by 500,000+ miles.

✔ Improve fuel efficiency and power output.

✔ Reduce downtime and avoid costly repairs.

Parts Catalog for Cummins 4B Marine Engine

Parts Catalog for Cummins 4BT Marine Engine

Parts Catalog for Cummins 4BTA Marine Engine

Parts Catalog for Cummins 6B Marine Engine

Parts Catalog for Cummins 6BT Marine Engine

Parts Catalog for Cummins 6BTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588