Introduction

Routine maintenance is the cornerstone of keeping your Cummins C Series engines—whether it’s the 6C, 6CT, or 6CTA—running smoothly, efficiently, and reliably. These engines are engineered for durability, high performance, and long service life, but like any mechanical system, they require regular attention to perform at their best. A well-maintained engine not only reduces the risk of unexpected breakdowns but also optimizes fuel efficiency, reduces emissions, and extends the overall lifespan of critical components.

Parts Catalog for Cummins 6C Marine Engine

Parts Catalog for Cummins 6CT Marine Engine

Parts Catalog for Cummins 6CTA Marine Engine

This guide will cover:

- Service Intervals for oil changes, filters, and inspections

- A comprehensive Checklist for daily, monthly, and annual maintenance

- Best Practices for maintaining engine health

By following these guidelines, you can ensure your Cummins C Series engine remains a reliable workhorse in any application.

1. Service Intervals for Oil Changes, Filters, and Inspections

Adhering to recommended service intervals is crucial for the longevity and performance of your Cummins C Series engine. The following intervals are general guidelines based on standard operating conditions. For engines operating in extreme environments (e.g., heavy dust, high humidity, extreme temperatures), maintenance may need to be performed more frequently.

A. Oil Change Intervals

Regular oil changes are critical because oil lubricates moving parts, reduces friction, and helps dissipate heat. Over time, oil breaks down, loses its viscosity, and accumulates contaminants, which can lead to engine wear.

- Standard Oil Change Interval:

- Every 250–500 hours of operation or every 6 months, whichever comes first.

- For severe conditions (e.g., dusty environments, heavy loads), reduce to every 250 hours.

- Oil Filter Replacement:

- Replace the oil filter with every oil change to prevent contaminants from circulating in the engine.

- Use high-quality filters designed for Cummins engines.

- Oil Type:

- Use SAE 15W-40 diesel engine oil that meets or exceeds API CI-4 or newer standards.

- Use SAE 15W-40 diesel engine oil that meets or exceeds API CI-4 or newer standards.

Lubrication System & Related Components for Cummins 6C Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CT Marine & Industrial Engines

Lubrication System & Related Components for Cummins 6CTA Marine & Industrial Engines

B. Fuel Filter Replacement Intervals

The fuel filter prevents dirt, water, and debris from reaching the injectors, where even minor contaminants can cause damage.

- Primary Fuel Filter (Water Separator):

- Inspect and drain water from the separator weekly or as needed.

- Replace every 250 hours or at least twice a year.

- Secondary Fuel Filter:

- Replace every 500 hours or with every second oil change.

- In poor fuel quality environments, replace more frequently.

Fuel System & Related Components for Cummins 6C Marine & Industrial Engines

Fuel System & Related Components for Cummins 6CT Marine & Industrial Engines

Fuel System & Related Components for Cummins 6CTA Marine & Industrial Engines

C. Air Filter Maintenance

A clean air filter ensures proper airflow, which is essential for efficient combustion and optimal performance.

- Inspection Interval:

- Inspect the air filter every 250 hours or more often in dusty conditions.

- Use a restriction gauge if available to monitor airflow resistance.

- Replacement Interval:

- Replace every 500 hours or when clogged, damaged, or indicated by the restriction gauge.

- Do not attempt to clean paper filters with compressed air, as this can damage the filter media.

Air Filter & Related Components for Cummins 6CT Marine & Industrial Engines

Air Filter & Related Components for Cummins 6CTA Marine & Industrial Engines

D. Coolant System Service

The cooling system prevents overheating and maintains engine temperature within safe operating limits.

-

Coolant Level Check:

- Check daily before starting the engine.

- Ensure the coolant level is between the MIN and MAX marks when the engine is cool.

- Coolant Change Interval:

- Replace coolant every 2 years or 4,000 hours, whichever comes first.

- Use a 50/50 mix of antifreeze and distilled water with corrosion inhibitors.

- Radiator Inspection:

- Inspect for debris, leaks, and corrosion monthly.

- Clean as needed to ensure proper airflow.

Fresh Water Pump for Cummins ISB 6.7, QSB 6.7, 6C, 6CT, 6CTA Engines

Freshwater Cooling System & Related Components for Cummins 6C Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6CT Marine & Industrial Engines

Freshwater Cooling System & Related Components for Cummins 6CTA Marine & Industrial Engines

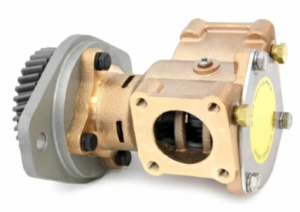

Marine sea raw water pump for Cummins – 6BT, 6BTA – 6C, 6CT, 6CTA – QSB – QSL

Raw Water Pump & Related Components for Cummins 6C Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CT Marine & Industrial Engines

Raw Water Pump & Related Components for Cummins 6CTA Marine & Industrial Engines

E. Valve Adjustment Intervals

Valve lash must be properly adjusted to maintain engine performance, prevent valve damage, and ensure efficient combustion.

- Adjustment Interval:

- Check and adjust valve lash every 1,000 hours or annually, whichever comes first.

- Requires specialized tools like feeler gauges and valve adjustment wrenches.

Valve & Related Components for Cummins 6C Marine & Industrial Engines

Valve & Related Components for Cummins 6CT Marine & Industrial Engines

Valve & Related Components for Cummins 6CTA Marine & Industrial Engines

F. Additional Inspections

- Belts and Hoses:

Coolant hose, silicone

- Inspect monthly for signs of wear, cracks, or looseness.

- Replace if frayed, glazed, or showing signs of deterioration.

- Battery Maintenance:

Starter for Detroit Diesel – Cummins, 12 Volts – RH – New

- Check terminals for corrosion and ensure connections are tight monthly.

- Test the battery voltage and charge level quarterly.

- Exhaust System:

Exhaust Manifold Marine for Cummins 6C, 6CT, 6CTA

- Inspect for leaks, cracks, or loose connections every 250 hours.

- Inspect for leaks, cracks, or loose connections every 250 hours.

2. Checklist for Daily, Monthly, and Annual Maintenance

A structured maintenance schedule helps prevent unexpected failures and ensures that all components are serviced regularly. Here’s a breakdown of what to check daily, monthly, and annually.

A. Daily Maintenance Checklist

Daily checks are designed to catch minor issues before they become major problems.

- ✅ Check Engine Oil Level

- ✅ Inspect Coolant Level

- ✅ Drain Water from Fuel/Water Separator (if equipped)

- ✅ Inspect for Visible Leaks (oil, fuel, coolant)

- ✅ Check Belts and Hoses for Cracks or Fraying

- ✅ Ensure Battery Connections Are Tight and Corrosion-Free

- ✅ Observe Engine Performance for Unusual Noises, Smoke, or Vibrations

B. Monthly Maintenance Checklist

Monthly checks involve a more thorough inspection to identify wear and tear that may not be visible during daily checks.

- ✅ Inspect Air Filter for Clogs or Damage

- ✅ Check the Radiator and Cooling System for Leaks or Debris

- ✅ Inspect Exhaust System for Leaks and Secure Mountings

- ✅ Check Battery Voltage and Test Charging System

- ✅ Inspect Fuel Lines for Cracks, Leaks, or Chafing

- ✅ Lubricate Throttle Linkages and Moving Components

C. Quarterly Maintenance Checklist

Cummins fuel filter, for Cummins 6C8.3, 6CT8.3, 6CTA8.3, ISC, QSC, L10, ISL, QSL engines.

Every three months or approximately every 250–500 hours, perform more detailed inspections and services.

- ✅ Change Engine Oil and Replace Oil Filter

- ✅ Replace Fuel Filters (Primary and Secondary)

- ✅ Inspect and Test the Alternator and Starter

- ✅ Check Coolant Concentration and Add Corrosion Inhibitor as Needed

- ✅ Inspect and Adjust Drive Belts

- ✅ Perform Diagnostic Scan (for electronically controlled models)

D. Annual Maintenance Checklist

Annual maintenance should cover every major component to ensure long-term engine health.

- ✅ Adjust Valve Lash (every 1,000 hours or annually)

- ✅ Flush and Replace Coolant

- ✅ Inspect Turbocharger for Excessive Play or Oil Leaks

- ✅ Perform Full Compression Test

- ✅ Inspect Engine Mounts for Wear or Damage

- ✅ Clean and Inspect Fuel Injectors

- ✅ Replace Crankcase Breather Filter

- ✅ Check and Calibrate Sensors (temperature, pressure, etc.)

3. Best Practices for Maintaining Engine Health

Routine maintenance is about more than just following a schedule. Implementing best practices can help you get the most out of your Cummins C Series engine.

A. Use High-Quality Parts and Fluids

- Always use genuine Cummins parts or high-quality aftermarket equivalents.

- Use certified lubricants and coolants that meet the engine’s specifications to prevent premature wear.

- Replace filters regularly with OEM or equivalent filters to maintain optimal engine performance.

B. Warm Up and Cool Down the Engine Properly

- Allow the engine to warm up before applying full load to ensure proper oil circulation and reduce thermal stress.

- After heavy use, let the engine idle for 3–5 minutes before shutdown to allow the turbocharger to cool gradually, preventing oil coking.

C. Monitor Engine Performance Regularly

- Pay attention to unusual noises, vibrations, or smoke. Changes in engine behavior often indicate developing issues.

- Keep track of fuel consumption. A sudden drop in fuel efficiency can signal injector problems, fuel system leaks, or engine wear.

D. Maintain Cleanliness

- Keep the engine bay clean and free from debris. Dirt and grime can hide leaks and contribute to component wear.

- Clean air filters regularly, especially in dusty environments, to prevent contaminants from entering the combustion chamber.

E. Perform Regular Diagnostic Scans

- For electronically controlled engines (6CTA), perform regular scans using Cummins INSITE or compatible diagnostic tools to detect issues early.

- Address fault codes promptly to prevent minor issues from escalating into major failures.

F. Maintain Accurate Maintenance Records

- Keep detailed records of all maintenance performed, including dates, operating hours, parts replaced, and services completed.

- This helps track wear patterns, ensures timely servicing, and increases the engine’s resale value.

Common Mistakes to Avoid in Routine Maintenance

- Ignoring Minor Leaks: Small leaks can lead to major issues if left unchecked.

- Over-Tightening Bolts: Use a torque wrench to avoid damaging components.

- Using the Wrong Oil or Coolant: Always verify specifications in the engine manual.

- Skipping Valve Adjustments: Neglecting valve lash adjustments can cause poor performance and premature wear.

- Failing to Bleed Air from the Fuel System: Air pockets can cause hard starting and performance issues.

Conclusion

Routine maintenance is the key to keeping your Cummins C Series engines (6C, 6CT, 6CTA) running efficiently and reliably. By following recommended service intervals, adhering to detailed checklists, and implementing best practices, you can extend the lifespan of your engine, reduce operating costs, and prevent costly breakdowns.

A well-maintained Cummins engine isn’t just about performance—it’s an investment in reliability, safety, and long-term efficiency. Whether you’re operating in the harsh conditions of a construction site, out at sea, or managing a fleet of trucks, proper maintenance will ensure your engine continues to deliver the power and performance you depend on.

Parts Catalog for Cummins 6C Marine Engine

Parts Catalog for Cummins 6CT Marine Engine

Parts Catalog for Cummins 6CTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588