Cummins 6BTA Parts

-Select Parts Category

Loading...

Loading... Parts for Cummins 6BTA Engines

Dependable Cummins 6BTA Marine Engine Parts – In Stock and Ready to Ship

The Cummins 6BTA engine—an advanced version of the renowned 6BT platform—is a turbocharged 5.9L inline-six powerhouse engineered for heavy-duty marine service. Built for endurance, torque, and low-RPM efficiency, the 6BTA thrives in continuous-use marine environments, making it a preferred choice for propulsion systems, onboard generators, pump drives, and workboat operations.

At Diesel Pro Power, we specialize in supplying Cummins 6BTA marine engine parts that meet OEM specifications and exceed the expectations of marine professionals. Our large, ready-to-ship inventory includes everything from overhaul kits to gauges, injectors, filters, cables, and more. With rapid global shipping—within 24 hours—our team ensures that you get the parts you need when you need them.

Buy Cummins 6BTA Marine Parts Online – Hassle-Free, Global, Accurate

We offer a streamlined, secure, and accurate online ordering system designed to support professional marine operations. Whether you're outfitting a harbor tug, repairing a fishing vessel, or overhauling a standby generator on a cargo ship, we have the inventory and expertise to get the job done right.

Piston Kits for Cummins 6BTA

Our marine-grade piston kits come with:

-

Piston

-

Ring set

-

Piston pin

-

Retainer clips

We also stock individual ring sets, available in standard and oversize configurations. These components are ideal for 6BTA engine rebuilds and performance restorations in commercial marine vessels and generator systems.

Crankshafts and Bottom End Components for Cummins 6BTA

We offer:

-

New crankshafts

-

Connecting rod and main bearing shell sets

-

Crankshaft plug kits

-

Thrust washers and hardware

These components are rigorously tested and built for engines running at high load levels in continuous-duty marine applications.

Sea Water Pumps for Cummins 6BTA

A reliable raw water pump is critical in marine environments. Our sea water pumps are constructed from marine-grade bronze and stainless steel and are built to handle the corrosive effects of seawater.

Pump components and accessories include:

-

Zinc anodes

-

Impellers

-

Seals and wear plates

-

Thermostats and water strainers

Whether you're running a keel-cooled setup or heat exchanger, we have a pump that fits your configuration and ensures proper thermal regulation.

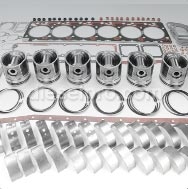

Rebuild Kits for Cummins 6BTA

When it's time for a full engine refresh, our engine overhaul kits include everything you need for a marine-grade rebuild:

-

Upper and lower gasket sets

-

Pistons and ring sets

-

Crankshaft and connecting rod bearing sets

-

Seals, washers, and grommets

-

Camshaft bushings (if required)

These kits are available for multiple CPL configurations and can be matched to your engine serial number for guaranteed fit and performance.

Injectors and Fuel System Components for Cummins 6BTA

Precision fuel delivery is critical in marine operations where engines run long hours under load. Our fuel system inventory includes:

-

Mechanical fuel injectors

-

Injector nozzles

-

Return lines and fittings

-

Injection pumps

-

Fuel lift pumps

-

Fuel filter assemblies

All injectors are marine-rated for corrosion resistance and calibrated for smooth idle, even at low RPMs typical of trawlers, ferries, and power generation sets.

Gasket Kits and Sealing Components for Cummins 6BTA

We carry complete Cummins 6BTA gasket kits for marine applications, including:

-

Upper gasket sets

-

Lower gasket sets

-

Full engine kits

-

Seal rings and o-rings

-

Thermostat housing gaskets

-

Oil pan and valve cover gaskets

Made from marine-grade materials, these gaskets resist breakdown from prolonged exposure to diesel, saltwater, and high-pressure oil and coolant systems.

Gauges, Switches, and Monitoring Equipment

Monitor your engine’s condition in real time with our marine-ready gauges and senders:

-

Oil pressure gauges

-

Water temperature gauges

-

RPM/tachometers

-

Boost pressure gauges

-

Exhaust temperature gauges

-

Sensor switches and senders

Built to withstand vibration and water exposure, these units are essential for safe and efficient marine engine operation.

Marine Cables and Engine Controls

Smooth throttle and shift operations depend on high-quality cables. We stock:

-

Push-pull marine cables

-

Throttle and gearshift linkages

-

Engine control heads

-

Cable clamps, mounts, and brackets

All control components are corrosion-resistant and suitable for use in open or enclosed marine environments.

Additional Cummins 6BTA Parts We Offer

-

Turbochargers and turbo repair kits

-

Starters (12V and 24V)

-

Alternators with corrosion-resistant housings

-

Air filters and intake hardware

-

Exhaust risers, elbows, and water-cooled manifolds

-

Belt kits, idlers, and pulleys

-

Oil coolers and cooler seals

-

Coolant treatment and rust inhibitors

-

Paints and touch-up kits (Cummins marine colors)

Every part in our catalog is hand-selected for marine engine reliability, compatibility, and longevity.

Why Buy Your Cummins 6BTA Marine Parts From Diesel Pro Power?

Over 15,000 Satisfied Customers Worldwide

We’ve proudly served professional fleets, shipyards, marina operators, and government agencies with parts they trust. Our reputation for quality and service is backed by 15,000+ global customers and growing.

Fast Shipping – Delivered Within 24 Hours

Thanks to our vast inventory and streamlined logistics, we ship most orders within 24 hours. Whether you’re docked in Miami, Manila, or the Middle East, your order arrives quickly and securely.

Secure, Accurate Website

Our e-commerce platform is designed for:

-

Fast navigation and search filtering

-

Secure checkout using the latest encryption

-

Mobile and desktop compatibility

-

Prepaid duties and taxes for international orders

Outstanding Customer Support

Our knowledgeable diesel specialists can:

-

Help identify your CPL and exact parts

-

Cross-reference old part numbers

-

Answer questions about installation

-

Help with shipping, customs, or warranty support

Call, email, or chat—we’re ready to help.

Where Cummins 6BTA Engines Excel in Marine Applications

The Cummins 6BTA’s power-to-weight ratio, reliability, and mechanical simplicity make it a favorite for:

Marine Use Cases

-

Commercial fishing boats

-

Tugs and pushboats

-

Ferries and passenger vessels

-

Patrol craft and harbor inspection vessels

-

Auxiliary systems: winches, pumps, and generators

-

Fire suppression and emergency pump setups

This engine thrives in conditions requiring constant torque, extended run cycles, and minimal maintenance downtime.

Maintenance Tips for Cummins 6BTA Marine Engines

Proper maintenance extends service life and prevents costly failures.

Weekly or Monthly Checks

-

Inspect impellers and raw water flow

-

Check zincs for corrosion

-

Monitor coolant and oil levels

-

Look for belt wear and alignment issues

-

Verify gauge accuracy

Seasonal Maintenance

-

Flush heat exchangers and coolant systems

-

Change fuel and oil filters

-

Inspect turbochargers and intake hoses

-

Replace seals and check for leaks

-

Test starter and alternator function under load

Keep a logbook for tracking hours and scheduled services, especially on high-use commercial vessels.

Recommended Replacement Cycles

|

Component |

Typical Interval |

|

Oil Filter |

Every 150–200 hours |

|

Fuel Filter |

Every 100–150 hours |

|

Raw Water Impeller |

Every 100 hours or seasonally |

|

Zinc Anodes |

Every 3–6 months |

|

Thermostat |

Every 2 years |

|

Injectors |

Every 3,000 hours |

|

Belts |

Every 2 years |

|

Fresh Water Pump |

Every 2–3 years |

|

Cylinder Head |

As needed (overheat, crack) |

Order Online or Contact Diesel Pro Power Today

Ordering your Cummins 6BTA marine engine parts is fast and simple.

Call Us

-

U.S. & Canada: 1-888-433-4735

-

International: +1-305-545-5588

-

Hours: Monday–Friday, 8 AM–5 PM EST

Or Send Us an Email

Send your engine serial number or photos and we’ll match parts for you.

Why Marine Professionals Choose Diesel Pro Power for Cummins 6BTA Support

-

100% marine and industrial focus

-

Massive in-stock inventory

-

Expert technical support

-

Global shipping in 24 hours

-

Trusted by thousands of professionals worldwide

Engine Specifications & Applications of the Cummins 6BTA Engine

Introduction to the Cummins 6BTA

The Cummins 6BTA is the most powerful and refined evolution of the original 6B engine platform. As a 6-cylinder, 5.9-liter turbocharged and aftercooled diesel engine, the 6BTA combines robust construction with enhanced power output, torque, and cooling performance. It represents a significant leap forward from earlier 6B and 6BT configurations, providing greater horsepower and thermal efficiency while maintaining the core benefits of mechanical simplicity and durability.

The 6BTA is widely recognized in the diesel aftermarket for its adaptability in marine, industrial, construction, agricultural, and power generation applications. By integrating an aftercooler (also known as an intercooler), the engine benefits from reduced intake air temperatures, allowing more oxygen-rich combustion, increased efficiency, and more power without increasing displacement.

In pre-electronic forms, the 6BTA is prized for its mechanical fuel injection, non-emissions-restricted design, and long service intervals, making it one of the most trusted and field-serviceable diesel engines in the world.

Cummins 6BTA Engine Specifications

Specification

Details

Configuration

Inline 6-cylinder, 4-stroke diesel

Displacement

5.9 liters (359 cubic inches)

Bore x Stroke

4.02 in x 4.72 in (102 mm x 120 mm)

Aspiration

Turbocharged and Aftercooled (Air-to-Air or Air-to-Water)

Fuel System

Mechanical direct injection (Bosch rotary or inline pump)

Compression Ratio

17.3:1

Horsepower Range

160–210 HP @ 2,500–2,800 RPM

Peak Torque

440–600 lb-ft @ 1,600–1,800 RPM

Cooling System

Liquid-cooled, high-efficiency water pump

Oil Capacity

Approx. 16 quarts (15 liters)

Dry Weight

~1,100–1,200 lbs (499–544 kg)

Flywheel Housing

SAE #2 or #3

Emissions Tier

Pre-Tier 1 (mechanical, non-electronic)

Expected Service Life

15,000–20,000+ hours with regular maintenance

The aftercooled design is a major differentiator, allowing the 6BTA to deliver higher performance while maintaining optimal combustion temperatures, improving both fuel economy and engine longevity. This makes it especially effective in high-load and high-temperature applications.

Common Applications of the Cummins 6BTA Engine

Thanks to its exceptional power density and simplicity, the 6BTA has a strong footprint in heavy-duty marine auxiliary systems, industrial equipment, construction machinery, power generation, and agricultural platforms. It excels in scenarios where continuous operation, torque-heavy performance, and low-maintenance design are critical.

1. Marine Auxiliary and Genset Applications

The Cummins 6BTA is a top choice for marine diesel generators and auxiliary propulsion systems, especially where high torque, thermal efficiency, and reliability are essential.

Marine Use Cases:

-

Onboard diesel generators (80–120 kW)

-

Hydraulic pump engines for winches, cranes, or stabilizers

-

Desalination plant and bilge pump drives

-

Refrigeration compressor units

-

Fire pump engines

-

Secondary propulsion for support or utility vessels

With turbocharging and aftercooling, the 6BTA performs better under load and in high-temperature engine rooms. Marine operators value its mechanical fuel system, which resists humidity and salt corrosion while enabling easy field diagnostics.

2. Industrial and Power Generation

The 6BTA powers mid- to large-frame diesel generator sets for both standby and continuous-duty installations. Its strong torque output at low RPM makes it particularly reliable in steady-state applications.

Industrial Generator Applications:

-

Oilfield trailers and field power units

-

Rural electrification gensets (prime or backup)

-

Mobile generator skids and containers

-

Facility backup generators (commercial and institutional)

-

Power units for pumping or municipal utilities

Thanks to its mechanically governed injection and minimal sensor reliance, the 6BTA remains a strong option for users in environments where Tier 4 Final electronics are impractical or cost-prohibitive.

3. Construction & Heavy Equipment

The Cummins 6BTA is trusted in mid- to heavy-duty off-road machinery, where its torque and durability help power hydraulic systems, loaders, and drive trains.

Common Equipment:

-

Large skid steers and loaders

-

Material handlers and boom lifts

-

Cranes and drilling platforms

-

Mining auxiliary equipment

-

Pavers, trenchers, and grinders

Construction companies benefit from the extended service intervals and strong fuel economy the 6BTA delivers, reducing downtime and operating cost on long shifts and in rugged terrain.

4. Agricultural Equipment

In the agricultural sector, the 6BTA shines as a stationary or mobile power source for high-demand, continuous-duty operations such as irrigation, grinding, or harvesting.

Agricultural Applications:

-

Diesel-powered irrigation systems

-

Feed mixing and milling equipment

-

Crop dryer engines

-

Auger and conveyor drives

-

Generator power for remote farming facilities

The turbo-aftercooled configuration ensures power consistency even under seasonal peak loads. Additionally, its air handling design reduces carbon buildup and fouling, helping it withstand high-dust environments often found in agriculture.

5. Oilfield and Utility Applications

The 6BTA is widely used in the oil and gas industry for powering non-drilling systems, where reliability and high-output mechanical power are necessary for operations in remote locations.

Oil & Gas Use Cases:

-

Mud pump drive engines

-

Skid-mounted gensets and compressors

-

Hydraulic pump engines for pipe handling or winches

-

Mobile well service and light towers

-

Transfer pump systems

Oilfield operators prefer the mechanical 6BTA over electronic Tier 4 engines because it reduces failure points and eliminates the need for DEF, SCR systems, or complex diagnostic tools in remote regions.

6. Export and Repower Markets

The Cummins 6BTA remains one of the most desirable legacy repower engines and is frequently exported to countries without strict emissions regulations.

Export Applications:

-

Rebuilt gensets shipped to Africa, Asia, and Latin America

-

Agricultural and construction machinery retrofits

-

Industrial utility engines for international NGOs

-

Marine support engines for workboats and ferries

-

Military surplus vehicle repowering

Its reputation for reliability and global support makes the 6BTA one of the most commonly rebuilt and exported mechanical diesel engines in the world.

Key Advantages of the Cummins 6BTA

-

Turbocharged & Aftercooled Power – Greater power density and torque with optimal combustion temperatures.

-

Mechanical Reliability – Non-electronic fuel system simplifies diagnostics and repair in any region.

-

Global Support – Parts availability and rebuild kits are extensive across continents.

-

Fuel Efficiency – Low fuel consumption at optimal RPM, especially under load.

-

High Load Capacity – Designed for systems that run at or near max output continuously.

-

Extended Lifespan – Easily surpasses 20,000 hours with consistent maintenance.

-

Cold Start Ready – Reliable starting performance in both tropical and cold climates.

-

Aftercooler Benefits – Reduces heat soak, improves volumetric efficiency, and extends component life.

Conclusion

The Cummins 6BTA is the most capable engine in the 6B family, offering enhanced horsepower and torque through turbocharging and aftercooling, all while retaining the mechanical dependability and field-serviceability that made the platform famous.

It is trusted worldwide across industries that demand continuous operation, ease of maintenance, and low operating costs, from marine auxiliary systems to remote generators, oilfield utility engines, and mobile construction platforms.

With support from a global aftermarket network and a service life measured in decades, the 6BTA remains one of the most sought-after engines for demanding marine and industrial applications. Whether you're repowering legacy equipment or building new installations in export markets, the 6BTA offers unmatched reliability and long-term value.

Additional Resources

Marine Cummins 6BTA Component Maintenance Life

Exploring Cummins 6BTA Engines: Features and Benefits

Oil Pressure Sensors for 6BTA 5.9L Cummins Engines: Essential for Reliable Performance

Guide To Buying A Cummins 6BTA Overhaul Kit

A Step-by-Step Guide to Installing a Cummins 6BTA Sea Water Pump

Boats That Use The Cummins 6BTA Engine

FAQ About The Cummins 6BTA Engine

Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA EnginesFAQ: Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

Introduction - Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Understanding Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

General Maintenance Requirements for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Oil and Lubrication Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cooling System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Fuel System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Air Intake and Turbocharger Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cylinder Head and Valve Adjustment for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Electrical System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Exhaust System and Emissions Control for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Common Problems and Troubleshooting Guide for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Major Overhaul and Rebuild Considerations for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Storage and Long-Term Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Recommended Aftermarket Parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Conclusion: Ensuring Long-Term Reliability for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

-

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588