Cummins ISB 6.7 Parts for Australia - Rebuild Kit Section

Loading...

Loading... Cummins ISB 6.7 Overhaul Kits by CPL Number

If you're looking to rebuild your Cummins ISB 6.7L engine, Diesel Pro Power provides premium-quality overhaul kits compatible with a range of CPL numbers. Whether you're experiencing loss of power, excessive oil consumption, or white smoke on startup, these kits are designed to restore factory performance with OE-quality components.

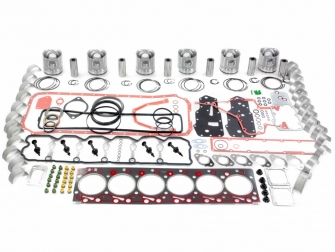

All overhaul kits listed below include pistons, rings, liners (where applicable), rod and main bearings, cam bearings, a full gasket set, and other required hardware. Kits are organized by CPL number to ensure proper fitment. Compression ratios are provided when applicable to help match your engine’s exact configuration.

Overhaul Kit for Cummins ISB 6.7L Compatible with CPLs 1995, 1998, 2048, 3602, 8530, 8782

Kit Features:

-

1-piece piston design: This style offers greater durability under high thermal stress and simplifies piston installation.

-

Standard size components: Designed for blocks and rods that are within factory wear limits.

-

Rear gear train configuration: Be sure your engine has a rear gear train before selecting this kit.

Common Failure Symptoms:

-

Loss of compression during cold starts

-

High crankcase pressure or blow-by

-

Fuel dilution and premature oil breakdown

-

Audible piston slap or excessive valvetrain noise

Compression Ratio: Typically 17.3:1 – ideal for standard diesel performance and emissions compliance. A higher compression ratio increases combustion efficiency and cold start performance.

Understanding Compression Ratios in ISB 6.7 Rebuilds

Your engine’s compression ratio significantly affects how it performs and starts. The most common ISB 6.7 configurations feature compression ratios between 17.0:1 and 17.3:1, but exact figures depend on your piston crown design and cylinder head machining.

-

Higher compression (17.3:1 and above): More efficient combustion and better cold-starting but slightly increased stress on internals.

-

Lower compression (16.5:1 – 17.0:1): Typically used in turbocharged applications for better high-end power.

Always verify the correct ratio for your CPL before ordering.

Matching Your Overhaul Kit by CPL Number

A CPL (Control Parts List) number ensures that all hardware and emissions components match your engine’s original design. Common CPLs for ISB 6.7 engines include:

-

CPL 1995, 1998, 2048: Medium-duty applications, often used in on-highway trucks or buses.

-

CPL 3602, 8530, 8782: Found in newer rear gear train configurations, often marine or industrial variants.

To locate your CPL, look for the dataplate on the gear housing or valve cover.

Additional Parts for Cummins ISB 6.7 Rebuilds

We highly recommend adding the following components during your engine overhaul to ensure maximum longevity and performance.

Nozzle to Cool Pistons

Part #: 4937308

Used in: Cummins B, BT, BTA, ISB, QSB engines

Why It Matters: These nozzles spray oil onto the underside of the piston to reduce thermal stress and prevent piston scuffing. Always replace during a major overhaul.

Crankshaft Seal Kits

-

Front Crankshaft Seal Kit

Includes: Seal and sleeve

Use Case: Prevents oil leaks from the front crank pulley area. Should be replaced anytime the timing cover is removed. -

Rear Crankshaft Seal Kit (Wet Clutch Engines)

Includes: Double-lip seal and sleeve

Use Case: Vital for sealing oil at the rear of the crankshaft, especially in applications with wet clutch housings.

Calibration and Service Tools

-

Feeler Gauge (.002"–.025")

Purpose: Used to calibrate valve lash, a critical step in reassembly that affects performance and emissions. -

Piston Ring Assembly Tool

Use Case: Speeds up ring installation and prevents breakage or distortion during reassembly. -

Oil and Fuel Filter Removal Wrenches

Designed specifically for Cummins filters, these tools ensure correct torque application and avoid housing damage.

Filtration Components

-

Cummins Fuel Filter

Thread: M16 x 1.5"

Filters out particulate contaminants to protect your fuel system during and after the rebuild. -

Fuel Filter & Water Separator Combo

Combines filtration with water separation to prevent injector damage from moisture in fuel. -

Cummins Oil Filter

Spin-on filter with standard 1-16 UN thread size and optimized micron rating for diesel applications.

Fluids, Sensors & Maintenance Support

-

Radiator Cleaner

Ideal for flushing coolant passages after head gasket failure or during block cleaning. -

Temperature Switch (205°F)

Ensures your engine fan or alarm activates at the correct temperature. -

Mechanical & Electric Gauges

Keep tabs on engine vitals like oil pressure, water temperature, and voltage.

When to Consider an Engine Overhaul for Your ISB 6.7

Symptoms that indicate your Cummins ISB 6.7L may need a rebuild:

-

White smoke or blue smoke during startup or acceleration

-

Low compression readings on one or more cylinders

-

Consistently low oil pressure, even after replacing filters and using the correct viscosity oil

-

Rattling noises or piston slap from the lower end

-

Loss of power under load or while towing

The Diesel Pro Power Advantage

With over 40,000 satisfied customers worldwide, Diesel Pro Power is trusted by commercial fleets, marine operators, and independent shops alike. Our overhaul kits are rigorously tested for durability and compatibility, and our expert staff can help you identify the correct CPL or kit if you're unsure.

We also stock supporting tools, sensors, and specialty hardware not found in typical retail channels—ensuring your ISB 6.7 rebuild is done right the first time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588