Twin Disc MG 509 Marine Transmission Parts for Australia - MG 509 Rebuilt Section

Loading...

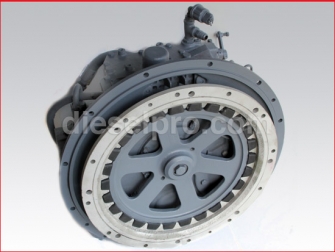

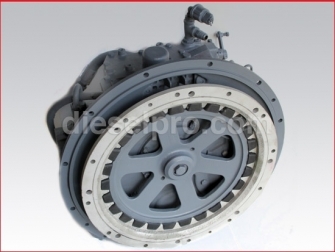

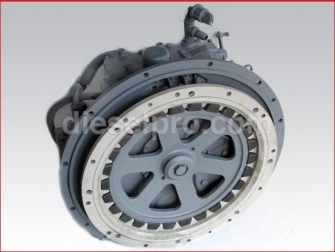

Loading... Twin Disc MG509 Marine Transmission Parts — Rebuilt MG509 Gear Section

When your vessel relies on a Twin Disc MG509, every shift, throttle change, and docking maneuver depends on a gearbox that engages smoothly and holds power under load. This section gathers our rebuilt MG509 marine transmissions by ratio and case style—organized so you can quickly match the correct 509 for your hull, engine, and duty profile. Each unit is professionally rebuilt, dynamically tested, and sold on exchange with a refundable core deposit so you can minimize downtime while maintaining OEM performance. You’ll also find complementary components—like the MG 509 Ring Drive (SAE #1)—that make installation straightforward and help ensure long-term reliability.

Below, you’ll find detailed overviews of the MG509 in the most requested ratios: 1.50:1, 2.00:1 (Shallow Case), 2.50:1 (Shallow Case), 3.00:1 (Shallow Case), 4.00:1 (Deep Case), and 4.50:1 (Deep Case), followed by the MG 509 Ring Drive. For each ratio, we outline typical applications, case-style considerations, cooling and lubrication notes, rotation and mounting guidance, and what to check on your current setup before you order. The goal is simple: make it easy to choose the right MG509 the first time—and get back on the water with confidence.

MG509 1.50:1 — Rebuilt

Overview & use cases

A 1.50:1 reduction is a versatile choice for lighter workboats, fast planing hulls, pilot boats, and recreational conversions where you want to keep propeller RPM relatively high while still gaining the torque multiplication you need for holeshot and mid-range efficiency. With a 1.5:1 ratio, prop sizing often trends smaller in diameter with higher pitch compared to deeper reductions, which can be advantageous when you’re managing tip clearance or tunnel limitations.

Why operators choose 1.5:1

-

Responsive acceleration: Quicker throttle response for vessels that run short legs or frequent harbor maneuvers.

-

Speed retention: Helps preserve top-end speed on engines that live in the upper third of the power band.

-

Simplified prop sourcing: Many common prop families and diameters are readily available in ranges compatible with this ratio.

Fitment checkpoints

-

Bell housing & ring gear: Verify your housing is SAE #1 and confirm ring gear pitch to pair with the MG 509 Ring Drive (see component listing below).

-

Shaft coupling & output flange: Confirm bolt circle and pilot to match your shaft coupling.

-

Mount geometry: On repowers, measure stringer height and foot pad spacing so your mounts sit naturally without shims.

-

Cooling loop: Ensure your existing oil cooler is sized for MG509 flows and that raw-water supply and return hoses are in good condition.

Common applications

Crew boats, pilot boats, small patrol craft, fast lobster/day boats, and recreational conversions with mid-to-high power-to-weight ratios.

MG509 2.00:1 — Rebuilt (Shallow Case)

Overview & use cases

A 2.00:1 reduction—especially in a shallow case—hits the sweet spot for mixed-use vessels that balance dockside control, efficient cruise, and predictable reverse authority. The shallow case is favored where space is tight around the gearbox bay or where service access needs to be maximized.

Shallow case advantages

-

Compact envelope: Eases installation in narrow engine rooms, retrofits, and vessels with tight shaft angles.

-

Service access: Improves reach to coolers, lines, and linkages in cramped housings.

Performance notes

-

Prop sizing latitude: 2.00:1 opens the door to moderately larger diameter props, improving bite at displacement speeds without overloading the engine at cruise.

-

Harbor handling: Adds low-speed authority for traps, towing short sets, or slipping into crowded docks.

Pre-order checklist

-

Verify input rotation and confirm controls are compatible (mechanical or electronic actuation).

-

Inspect engine flywheel ring gear wear and confirm tooth profile is within spec.

-

Check oil cooler condition; consider replacing to safeguard your rebuilt unit.

MG509 2.50:1 — Rebuilt (Shallow Case)

Overview & use cases

At 2.50:1, the MG509 transitions into a work-first profile suited for heavier displacement hulls, pushing larger wheels efficiently at realistic cruise RPM. Operators running loaded workboats, multipurpose commercial craft, and utility vessels often select 2.50:1 to put more torque where it matters—at the prop.

Why 2.5:1 excels

-

Bigger prop, more bite: Enables larger diameter/appropriate pitch combinations that hold water under load.

-

Fuel efficiency at working speeds: Lets engines maintain a comfortable, sustained RPM at or near peak torque.

-

Reduced cavitation risk: Better propeller loading reduces slip in choppy, high-drag conditions.

Shallow case considerations

You retain the space- and service-friendly envelope of the shallow case while still achieving robust reduction. Make sure the aft clearance in your shaft alley can accommodate a slightly larger prop if you’re upsizing.

Installation tips (selection-focused)

-

Confirm shaft line alignment potential with existing struts and log.

-

Reassess propeller diameter options versus tunnel or skeg clearance.

-

Match throttle/shift control style to the transmission’s control valve and linkage geometry.

MG509 3.00:1 — Rebuilt (Shallow Case)

Overview & use cases

For displacement and semi-displacement hulls that carry weight—think small freighters, larger trap boats, tenders with heavy gear, or utility craft—a 3.00:1 reduction puts a premium on thrust and control. The MG509 in this ratio allows props that push significant water at maneuvering speeds while keeping your engine comfortably loaded.

Operational benefits

-

Exceptional low-speed authority: Easier station keeping and slow-speed work.

-

Comfortable cruise: Lets the engine live at an efficient RPM even with high hull resistance.

-

Reverse power: Predictable stopping power when you need to check headway quickly.

Shallow case fitment

The shallow case helps preserve space in the engine room—which is useful when deeper reductions bring larger coolers and broader plumbing runs. Verify that engine-to-gear angle and shaft centerline height are compatible with mounts and bearers.

Selection notes

-

Confirm input spline/flywheel interface and the presence of any torsional coupling.

-

Evaluate cooling flow availability; deeper reductions can demand more thermal headroom.

-

Consider vibration isolation: deeper reductions sometimes reveal mount issues; plan fresh mounts if your current set is fatigued.

MG509 4.00:1 — Rebuilt (Deep Case)

Overview & use cases

A 4.00:1 reduction in a deep case is built for serious thrust at low speeds—think heavy displacement hulls, push boats, trawlers that drag gear, or utility vessels working against current. The deep case design allows additional internal volume and structural robustness appropriate for the increased torque multiplication and thermal loads that come with this ratio.

Deep case advantages

-

Enhanced structural capacity: Robust housing for sustained high-load operation.

-

Thermal management headroom: More room for fluid mass and cooler routing helps stabilize operating temperatures.

-

Service longevity: Ideal for operators who run long hours near working RPM for seasons at a time.

Propeller strategy

With 4.00:1, you’ll typically pursue the largest practical diameter and a conservative pitch to maximize grip and minimize slip. This approach is forgiving in chop and highly controllable near docks.

Readiness checklist

-

Cooler sizing: Confirm heat exchanger capacity is appropriate for a deep-reduction workload.

-

Shafting: Heavier loading at the wheel may warrant reviewing shaft diameter, keyway condition, and coupling fit.

-

Exhaust & intake: Ensure the engine can breathe cleanly at the lower RPMs associated with deeper reduction to prevent sooting.

MG509 4.50:1 — Rebuilt (Deep Case)

Overview & use cases

The 4.50:1 ratio represents the MG509’s focus on maximum thrust and slow-speed control. Deep case units in this range are selected for the hardest pulling applications where wheel diameter can be maximized, bollard pull matters, and engine efficiency is realized at relatively low crankshaft RPM.

Who picks 4.5:1

-

Heavy displacement commercial vessels that prioritize pull over speed.

-

Towing and utility operations in confined waterways.

-

Workboats that push barges, materials, or gear routinely.

Key selection insights

-

Verify gearcase clearance for the deeper housing, including service access to cooler lines.

-

Plan for mounting footprint—deep case feet may want more rigid bearers or revised fastener spacing.

-

Check controls and linkages; ensure you can achieve full throw without interference in tightly packed bays.

Control & feel on the water

At this reduction, clutch engagement should feel deliberate and smooth, with strong “bite” from the prop at idle-plus RPM. That gives precise docking and authoritative backing power when you need it most.

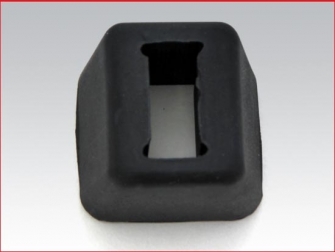

MG 509 Ring Drive — Housing Size SAE #1

What it does

The ring drive (often called a ring gear or engine drive ring) is the key coupling element that mates your engine flywheel to the MG509’s input. Proper tooth profile and concentricity are critical for vibration control and long clutch life.

When to replace

-

Visible wear or chipped teeth on your current ring gear.

-

Repower or transmission swap—it’s best practice to install a fresh ring drive to eliminate inherited vibration.

-

Flywheel service—if you’re in there for inspection, replacing the ring drive is cheap insurance.

Selection notes

-

Match SAE #1 housing and confirm the engine’s flywheel spec.

-

Inspect pilot bearing and input spline condition while you’re apart.

-

Keep a record of tooth count and pitch for future service.

Understanding MG509 Case Styles: Shallow vs. Deep

Shallow Case

-

Prioritizes compactness and access, ideal for vessels with tight spaces or retrofits that can’t accommodate a tall gearcase.

-

Works well through 2.00:1 to 3.00:1 reductions where envelope and serviceability are as important as pulling power.

-

Often simplifies hose runs and linkage routing, reducing the odds of interference.

Deep Case

-

Adds structural and thermal capacity ideal for 4.00:1 and 4.50:1.

-

Designed for sustained heavy loads where thrust takes priority over top speed.

-

Provides service life advantages when you operate many hours near working RPM with high propeller loading.

Rotation, Controls, and Mounting—Selection Notes (Catalog-Focused)

Input rotation & output direction

Match engine rotation with the MG509 specification you’re ordering. While many modern installations are standardized, legacy setups may have unique rotation requirements. If you’re unsure, document your current gear tag data and output direction in ahead gear at idle.

Controls

MG509 units are commonly compatible with mechanical or electronic control systems (via appropriate valves and linkages). Confirm throw and travel at the gearbox lever before commissioning so the clutches see full, clean engagement and release.

Mounting & alignment

-

Confirm SAE #1 bell housing on the engine side.

-

Verify footprint and bolt pattern on existing engine beds.

-

Plan a fresh alignment after installation; a rebuilt gear deserves a true shaft line to protect bearings and clutches.

Cooling & lubrication

Every rebuilt MG509 benefits from clean, properly sized coolers and unobstructed raw-water supply. If your current cooler is aged or questionable, consider replacement at the same time as the gear swap to safeguard your investment.

Choosing the Right MG509 Ratio for Your Vessel

Start with hull and mission

-

Planing & fast semi-planing hulls: 1.50:1 to 2.00:1 to preserve speed and throttle response.

-

Mixed-use workboats & heavier semi-displacement hulls: 2.00:1 to 3.00:1 for balanced control and efficiency.

-

Heavy displacement & towing: 4.00:1 to 4.50:1 to maximize thrust and low-speed authority.

Then layer engine characteristics

-

Identify your engine’s peak torque band and target cruise RPM.

-

Select a ratio that lets the prop load the engine efficiently at that RPM—neither lugging nor free-wheeling.

Finally, check the propeller envelope

-

Ensure the largest practical diameter fits your tunnel, skeg, and tip-clearance rules.

-

Tune pitch after sea trial to hit your rated wide-open throttle RPM under realistic load.

Exchange Program & Core Deposit—What to Expect

All MG509 rebuilt units in this section are sold with a refundable core deposit. That allows you to receive a ready-to-install gearbox quickly, keep your project moving, and return your core after the swap. When your used MG509 arrives and passes inspection (within normal rebuildable condition guidelines), the deposit is refunded. This keeps total cost predictable and reduces downtime for commercial operators.

Simple steps

-

Order the rebuilt unit that matches your ratio and case style.

-

Receive and install the gearbox, aligning and plumbing to your vessel’s systems.

-

Return your core—drained, capped, and reasonably clean—using the instructions provided.

-

Receive your refund once inspection confirms the core is rebuildable.

Tips for a smooth return

-

Cap or plug all ports to prevent leaks in transit.

-

Protect output and input splines.

-

Include any data tags that identify model and ratio if they are separate from the housing.

Quality & Testing You Can Count On

A rebuilt MG509 should feel like a trustworthy crew member: quiet, decisive, and consistent across long days. That’s why our units undergo dynamic spin testing to verify clutch engagement, pressure stability, and noise/temperature behavior before they leave the shop. While you’ll see core program and availability details on each product tile, behind the scenes the focus is on reliable, repeatable shifts and long seal life.

What dynamic testing catches

-

Out-of-family noises that indicate bearing issues.

-

Pressure irregularities that could shorten clutch life.

-

Thermal drift under load that points to cooler or internal bypass problems.

This testing gives you confidence that your MG509 will perform as expected from the first key-turn.

Installation Adjacencies Worth Considering (Catalog Companion Items)

While this section centers on the rebuilt transmissions and ring drive, many successful installs also address “adjacent” components at the same time to prevent callbacks and unscheduled downtime:

-

Oil coolers & hoses: A fresh cooler and new hoses reduce contamination risk and stabilize oil temperatures.

-

Mounts: Tired mounts transmit vibration and can misalign the driveline over time; fresh mounts protect bearings.

-

Shaft coupling hardware: New fasteners and a verified pilot fit help maintain concentricity.

-

Control linkages: Re-bushed linkages or updated electronic interfaces improve shift quality and reliability.

Ask us about complementary parts for your MG509 installation—we’ll help you bundle what you need.

How to Read Your Existing MG509 Tag (So You Order Once)

Before you order, grab the data from your existing transmission tag. Helpful details include:

-

Model: MG509.

-

Ratio: 1.50:1, 2.00:1, 2.50:1, 3.00:1, 4.00:1, or 4.50:1.

-

Case style: Shallow or Deep (where applicable).

-

Any rotation notes or unique configuration codes.

If your tag is missing: photograph the gearbox from multiple angles, note bell housing size (SAE #1 for the ring drive above), measure output flange pilot/b.c., and tell us your engine model and typical operating profile. We’ll help you triangulate the correct unit.

Troubleshooting Symptoms That Point to a Rebuild

If you’re debating whether to replace the gear now or later, these symptoms often indicate it’s time to act:

-

Slow or slipping engagement when shifting into ahead or astern.

-

Rising oil temperatures under normal workload despite a clean cooler.

-

Metal fines in the filter or oil (beyond minor break-in glitter).

-

Growling/rumbling noises that track with shaft speed.

-

Persistent oil leaks at seals or mating faces that return after reseal attempts.

A properly rebuilt MG509 eliminates these issues and protects your engine by ensuring the driveline loads predictably at all speeds.

Quick Order Guide (In Catalog Order)

-

Twin Disc MG509, 1.50:1 — Rebuilt

General-purpose ratio for quick throttle response and balanced cruise. -

Twin Disc MG509, 2.00:1 — Rebuilt (Shallow Case)

Space-efficient package with strong harbor handling and broad prop options. -

Twin Disc MG509, 2.50:1 — Rebuilt (Shallow Case)

Work-ready reduction for heavier semi-displacement hulls and mixed commercial duty. -

Twin Disc MG509, 3.00:1 — Rebuilt (Shallow Case)

High-thrust, low-speed control for weight-carrying vessels that value grip and predictability. -

Twin Disc MG509, 4.00:1 — Rebuilt (Deep Case)

Deep-reduction unit for serious displacement work and long hours on the job. -

Twin Disc MG509, 4.50:1 — Rebuilt (Deep Case)

Maximum thrust and slow-speed authority for towing, pushing, and heavy utility. -

Twin Disc MG 509 Ring Drive — SAE #1

The correct engine-to-gear interface for a smooth, long-life installation.

(Each item above is listed with live availability, core deposit details, and add-to-cart controls on this page.)

Why Buy Your Rebuilt Twin Disc MG509 From Diesel Pro Power

When downtime is measured in missed trips and lost revenue, you need a supplier that understands marine timelines and gets you dependable parts—fast. Diesel Pro Power pairs a deep in-stock inventory with seasoned product specialists who help you match the right MG509 to your hull and powerplant. We’ve served 40,000+ satisfied customers with professional packing, clear core-return instructions, and responsive support before and after the sale.

What sets us apart

-

Rebuilt quality you can trust: Professionally rebuilt MG509 units that are spin tested for clean engagement and stable operating temps.

-

Core deposit made easy: Straightforward exchange process and prompt refunds on rebuildable cores.

-

Marine-focused support: Talk to people who live and breathe marine powertrains—ratio selection, case style, and installation adjacencies.

-

Fast shipping, careful packing: Gearboxes and ring drives arrive protected and ready to install.

-

Comprehensive catalog: Pair your gearbox with the correct ring drive, cooler, mounts, coupling hardware, and more—on one order.

If you’re not certain which ratio or case style is right for your vessel, share a few details about your engine, current prop, and operating profile. We’ll help you choose the MG509 that delivers the control, thrust, and efficiency your work demands.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588