Cummins ISC Parts for Canada - Crankshaft Section

Loading...

Loading... Cummins ISC Crankshaft Parts Catalog

The Cummins ISC engine is one of the most versatile and durable mid-range diesel engines in the Cummins family, widely used in buses, vocational trucks, construction machinery, agricultural equipment, and industrial applications. At the heart of this engine lies the crankshaft, a critical rotating component that transforms the linear motion of the pistons into rotational force. Without a properly functioning crankshaft and its related components, the ISC cannot deliver the reliability, torque, and efficiency that operators depend on.

This catalog is dedicated to the Cummins ISC crankshaft and all related service parts, including crankshaft assemblies, main bearings, gasket sets, seals, vibration dampers, and gear housing components. Each product is engineered to meet Cummins standards, ensuring long service life and peak performance.

With more than 40,000 satisfied customers worldwide, Diesel Pro Power provides trusted Cummins ISC crankshaft parts that help extend the life of your engine, minimize downtime, and deliver lasting value.

Understanding the Role of the Crankshaft in the Cummins ISC

The crankshaft in the Cummins ISC engine is responsible for converting the up-and-down motion of pistons into rotational energy, which ultimately drives the vehicle or equipment. This simple description belies the complexity and precision required to keep the crankshaft functioning properly.

-

Load-bearing function: The ISC crankshaft absorbs tremendous forces generated by combustion. Each firing cylinder transmits force to the crankshaft journals, which must resist wear and distortion.

-

Balance and rotation: Counterweights built into the crankshaft balance the rotating assembly, reducing vibration and ensuring smooth operation at all RPM ranges.

-

Lubrication: Proper oil film between crankshaft journals and bearings is essential to prevent metal-to-metal contact.

-

Durability: ISC crankshafts are forged from high-strength steel alloys, designed to withstand heavy loads and long hours of continuous operation.

Because of these functions, maintaining crankshaft health is critical to ISC engine reliability. The following sections explore each component related to crankshaft operation.

New Cummins ISC Crankshaft Assemblies

Why Choose a New Crankshaft?

When rebuilding a Cummins ISC, the decision to install a new crankshaft versus regrinding the old one can determine the long-term outcome of the rebuild. New crankshafts are manufactured to Cummins’ original tolerances and specifications. They ensure perfect roundness of journals, precise balance, and material strength that has not been altered by fatigue.

Applications for New ISC Crankshafts

A new ISC crankshaft is recommended when:

-

The original crankshaft has cracks or fractures.

-

Journal surfaces are excessively worn or scored beyond repair limits.

-

The crankshaft has suffered heat damage due to lubrication failure.

-

Regrinding has already been performed and additional machining would exceed safe tolerances.

A fresh crankshaft restores the ISC engine to factory-level operation, providing the durability required for demanding applications such as transit buses, vocational trucks, and construction equipment.

Cummins ISC Crankshaft for CM850 Electronic Engines

Later versions of the Cummins ISC engine feature the CM850 electronic control module and a high-pressure common rail (HPCR) fuel system. These engines operate at higher injection pressures and tighter tolerances than earlier versions.

The crankshaft for CM850-equipped ISC engines is engineered to withstand:

-

Higher torsional loads caused by increased combustion pressures.

-

More precise timing requirements due to electronic injection.

-

Compatibility with advanced vibration dampers that reduce stress on the crankshaft.

Installing the correct crankshaft for CM850 ISC engines is critical to ensure smooth operation and compliance with modern emission standards.

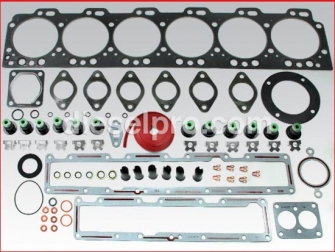

Gasket Sets for Cummins ISC Crankshaft Service

Whenever the crankshaft is removed or serviced, gasket sets are required to reseal the engine. Cummins offers both upper and lower gasket sets for the ISC platform.

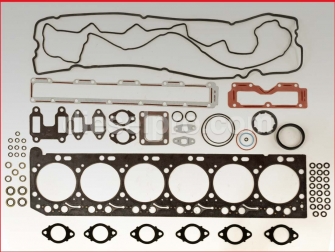

Upper Gasket Sets

The upper gasket set includes cylinder head gaskets, intake and exhaust gaskets, and seals for oil and coolant passages. While these components are above the crankshaft, they play a role in protecting lubrication and preventing contamination from reaching the lower end.

-

ISC Upper Gasket Set for CM850 Engines: Designed for engines with HPCR systems, ensuring compatibility with high-pressure sealing requirements.

-

ISC Upper Gasket Set for Standard Engines (≤450 HP): Suitable for earlier ISC models, balancing performance with affordability.

-

ISC Upper Gasket Set for EGR Engines: Tailored for engines with exhaust gas recirculation systems, with special sealing materials that withstand higher heat and soot loads.

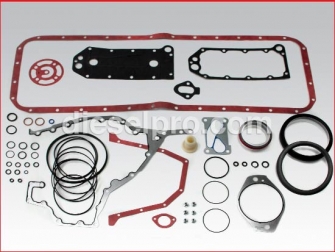

Lower Gasket Set

The lower gasket set is directly related to crankshaft service. It includes:

-

Oil pan gaskets.

-

Gear housing gaskets.

-

Seals for lower-end components.

This set is essential when removing the crankshaft for inspection, replacement, or bearing service. Proper sealing prevents oil leaks and contamination, protecting the freshly serviced crankshaft.

Crankshaft Bearings for Cummins ISC

Importance of Main Bearings

Crankshaft bearings (often called main bearings) provide a smooth, low-friction surface for the crankshaft journals to rotate against. They also maintain oil clearance, absorb vibration, and distribute loads evenly across the block.

Standard Size Bearings

Standard-size bearings are used when the crankshaft journals remain within factory tolerances. They are precision-machined to provide the exact clearance needed for reliable lubrication and rotation.

Oversize Bearings

If the crankshaft journals are reground during a rebuild, oversize bearings must be used to restore proper oil clearance. For the Cummins ISC, two common oversize options are available:

-

0.25 mm Oversize Bearings – Used after a light regrind.

-

0.50 mm Oversize Bearings – Used after a more extensive machining process.

Selecting the correct bearing size is critical. Incorrect clearances can lead to oil starvation, overheating, and catastrophic crankshaft failure.

Crankshaft Seals for Cummins ISC

Seals play a vital role in protecting the crankshaft by keeping oil inside the engine while keeping dirt and contaminants out.

Front Crankshaft Seals

The front crankshaft seal prevents oil leaks at the timing cover. The seal must withstand constant rotation, heat, and vibration. Cummins ISC front seal kits typically include:

-

The primary seal.

-

A wear sleeve to protect the crankshaft surface.

Rear Crankshaft Seals

The rear crankshaft seal prevents leaks where the crankshaft exits the block at the flywheel housing. ISC rear seals are available for different configurations:

-

Dry clutch housing applications.

-

Wet clutch housing applications with double-lip seals for added protection.

Replacing crankshaft seals during rebuilds prevents oil leaks that can quickly cause serious damage.

Vibration Dampers for Cummins ISC

A vibration damper, also known as a harmonic balancer, is mounted on the front of the ISC crankshaft. Its role is to absorb torsional vibrations that occur as cylinders fire and the crankshaft twists slightly under load.

Why Dampers Are Essential

Without a damper, torsional vibrations can:

-

Cause crankshaft fatigue and cracking.

-

Loosen bolts and components attached to the crankshaft.

-

Reduce overall engine smoothness.

Cummins ISC Damper Options

-

9.67” Outside Diameter Damper – Standard size with four bolt holes.

-

8.97” Outside Diameter Damper – Compact variant for alternate ISC configurations.

Both options are precision balanced to ensure crankshaft longevity and reduced vibration.

Gear Housing Gasket for Cummins ISC

The gear housing gasket seals the front gear train, where the crankshaft connects to timing gears. Proper sealing in this area is crucial because:

-

The crankshaft drives the camshaft, fuel system, and accessory gears.

-

Oil must be retained within the gear housing to lubricate moving components.

-

Leaks in this area can contaminate the timing gears and cause premature wear.

Best Practices for Servicing Cummins ISC Crankshafts

-

Always inspect journals for scoring, heat damage, or cracks before deciding on reuse or replacement.

-

Measure bearing clearances with plastigage or micrometers to ensure proper oil film thickness.

-

Replace seals and gaskets whenever the crankshaft is removed. Reusing old seals is a leading cause of post-rebuild oil leaks.

-

Use the correct vibration damper for your ISC model to prevent torsional stress.

-

Torque fasteners properly during installation to maintain crankshaft alignment.

Why Choose Diesel Pro Power for Cummins ISC Crankshaft Parts

With decades of experience and over 40,000 satisfied customers, Diesel Pro Power supplies high-quality Cummins ISC crankshaft components worldwide. Customers rely on Diesel Pro Power because:

-

All parts meet or exceed Cummins specifications.

-

Inventory is ready to ship, minimizing downtime.

-

Expert support ensures you get the correct ISC crankshaft part for your application.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588