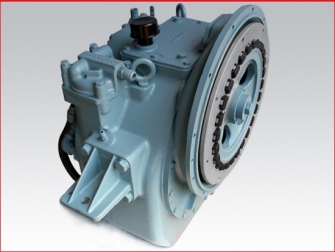

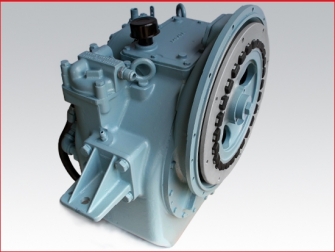

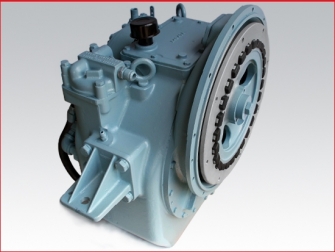

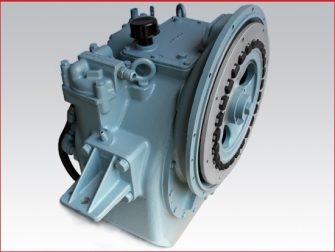

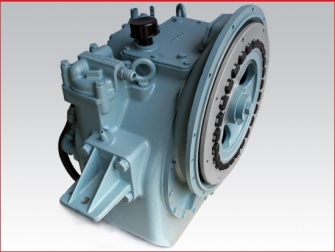

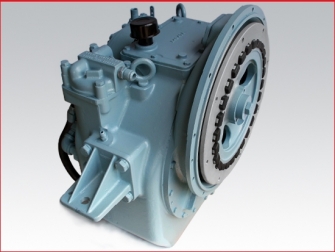

Twin Disc MG-514B Marine Transmission Parts - MG 514 Rebuilt Section

Loading...

Loading... Twin Disc MG-514B Rebuilt Marine Transmissions — Catalog Overview

When your vessel depends on a Twin Disc MG-514B to translate engine power into clean, controllable thrust, the choice of gearbox—and the people who stand behind it—matters. This catalog section focuses on fully rebuilt MG-514B marine transmissions in the exact ratios and case styles commercial operators ask for most: 2.00:1 (shallow case), 3.00:1 (shallow case), 4.00:1 (deep case), 4.50:1 (deep case), 5.00:1 (deep case), and 6.00:1 (deep case). Each unit is offered on an exchange basis with a refundable core deposit and ships ready for drop-in replacement once your coupling, mounts, and cooling circuit checks out. For owners and yards running crew boats, pilot boats, tugs, supply vessels, fishing boats, ferries, tour craft, and other hardworking platforms, the MG-514B series hits the sweet spot between robust torque capacity, compact envelope, and proven Twin Disc durability.

What’s here in the rebuilt section. Below you’ll find a buyer-focused guide to selecting the correct MG-514B ratio and case style, plus practical fitment notes for SAE #1 housings, input couplings, shaft rotation alignment, oil cooling, and control options. We also outline the ring drive for the MG-514B/514C family (SAE #1) that’s listed alongside the gearboxes—handy when you’re refreshing the driveline during a change-out. Throughout, we keep the emphasis on MG-514B so you can move from quote to installation with confidence and no guesswork.

Rebuilt Quality & Test Standards

Every MG-514B offered here is professionally rebuilt and spin-tested before it leaves the warehouse. That spin test is your assurance that the unit builds pressure, engages smoothly in both ahead and astern, and holds under load at temperature. The clutch packs, bearings, seals, and wear items are brought back to serviceable specification using proven procedures and quality components, and hydraulic performance is verified on a test stand so you don’t discover issues at the dock. The result is a gearbox that feels “right” from first start, with crisp engagement, predictable idle crawl, and strong, chatter-free acceleration.

Core Deposit & Exchange Process

Rebuilt MG-514B transmissions are sold with a refundable core deposit. You receive your rebuilt unit first; then, after your old MG-514B is removed, you send your complete core back in the provided crate. Once the core passes basic checks (complete, buildable, not windowed or catastrophically damaged), your deposit is refunded. This exchange model minimizes downtime—you can stage the replacement, complete alignment and hose routing on your schedule, and eliminate the risk of tying up the boat while waiting on a rebuild.

Shallow Case vs. Deep Case

The MG-514B family appears in two distinct case depths depending on ratio and output centerline geometry:

-

Shallow Case (2.00:1 and 3.00:1)

A more compact housing that fits tighter engine rooms and aligns easily with shafts on vessels that were originally spec’d for low to mid ratios. If your existing gearbox tag or service records specify a shallow case, stick with it—switching to a deep case changes output centerline height and can cascade into alignment and stringer modifications. -

Deep Case (4.00:1, 4.50:1, 5.00:1, 6.00:1)

The deep case provides the geometry needed for higher reduction ratios, increasing propeller torque multiplication and allowing larger-diameter wheels at lower shaft RPM. This is the go-to choice on heavy-lift workboats, trawlers, and displacement craft where bite and bollard pull trump top speed.

If you’re replacing “like with like,” simply match the case depth printed on your original data plate. If you’re revisiting ratio for a repower or propeller optimization, read the ratio guide below and consult your naval architect or prop shop before changing case depth.

MG-514B Gear Ratio Guide

Choosing the correct ratio is the single biggest performance decision you’ll make with an MG-514B. The ratio governs prop speed at a given engine RPM and, therefore, thrust, acceleration, cruise efficiency, and noise profile.

-

2.00:1 (Shallow Case)

Best for lighter planing hulls or fast utility craft where engine RPM is relatively high and you want snappy throttle response. This ratio keeps shaft speed up, which can help smaller propellers maintain grip during rapid throttle changes and dynamic maneuvers around docks or pilings. If your current boat already planes easily and cruises mid-range without excessive slip, 2:1 maintains that lively feel. -

3.00:1 (Shallow Case)

A versatile middle ground for multipurpose vessels that need stronger push off the line and improved backing authority without sacrificing too much top-end. Many crew boats, pilot boats, and heavier planing hulls run happily at 3:1—especially where fuel economy at “fast cruise” matters more than squeezing out maximum knots. Expect noticeably better low-speed control versus 2:1 while keeping acceleration brisk. -

4.00:1 (Deep Case)

The starting point for serious torque multiplication. If you’ve upsized prop diameter, increased blade area, or carry heavy lifts, 4:1 puts your wheel in the sweet spot where cavitation risk drops and bite increases. Backing into current, holding station near structures, or pushing alongside barges all feel more deliberate and surefooted. -

4.50:1 (Deep Case)

A smart step when you need more bollard pull and low-speed authority than 4:1 provides, but don’t want to over-slow the shaft for transit legs. Many displacement-speed workboats and trawlers find 4.5:1 hits a comfortable balance for daily operations—assertive thrust, calm wheel noise, and friendly fuel numbers at realistic RPM. -

5.00:1 (Deep Case)

A heavy-haul specialist. If your vessel spends most of its time towing, pushing, trawling, or carrying high static loads, 5:1 puts muscle where you use it. Expect exceptionally smooth gear engagement, strong reverse punch, and quieter prop dynamics at working speeds. You’ll size the prop accordingly to use the additional torque without overloading the engine—consult your prop shop to dial in diameter and pitch. -

6.00:1 (Deep Case)

Maximum torque multiplication in the MG-514B lineup. Choose 6:1 when the mission is all about thrust at controlled shaft RPM: towing gear, trap lines, heavy nets, or pushing into weather and current all day. The wheel turns slow and powerful, cavitation margin improves, and maneuvering is precise. Top speed drops on planing hulls, but for displacement or semi-displacement platforms it delivers outstanding control and push.

Rotation & Shafting Considerations

MG-514B units support the conventional right-hand/left-hand shaft conventions you see in twin-screw installations. If you’re running counter-rotating props, confirm rotation at the shaft (not the engine) and match the gearbox build configuration accordingly. Maintaining original prop rotation is the path of least resistance for steering balance and helm feel.

MG-514B Technical Specifications & Fitment Notes

Housing & Mounting (SAE #1)

The MG-514B commonly uses an SAE #1 housing, a widely used bellhousing size that simplifies integration across commercial diesel engines. The MG-514 Ring Drive (Housing Size SAE #1) listed in this section is the mating gear that ensures a precise mechanical interface between the engine’s flywheel and the transmission input. If your ring drive shows heat checking, chipped teeth, or fretting wear, replacing it during a gearbox swap is inexpensive insurance and saves the pain of future driveline vibration.

Engine beds and soft mounts are typically reusable during a like-for-like MG-514B replacement, but any change in case depth or ratio may alter output centerline enough to require shim adjustments. Your yard will check stringer height and shaft alignment as part of commissioning.

Input Coupling & Alignment

MG-514B input couplings must match your engine’s flywheel and pilot bore dimensions. Reusing a coupling that has seen severe heat or hammer marks invites chatter, so many operators refresh the coupling during a gearbox change. After bolting up, alignment should be verified warm at the shaft coupling in accordance with standard marine practice; a smooth MG-514B is a well-aligned MG-514B.

Lubrication & Cooling

Hydraulic marine gears depend on clean oil and stable temperature. Most MG-514B installations route transmission oil through a heat exchanger (seawater or jacket water cooled). During a change-out, confirm that the cooler, hoses, and strainer are clean and sized for your duty cycle. Excess exhaust backpressure, barnacles in coolers, or kinked hoses can raise oil temperature and shorten clutch life. If you operate in silt-heavy water or tropical climates, consider a maintenance calendar that inspects the cooler more often.

Controls, Trolling, and PTO

MG-514B units are typically configured for mechanical or hydraulic actuation with ahead/astern control from the bridge. Many fleets add a trolling valve for ultra-fine speed control when you need prop slip at idle—useful for trawling, purse seine work, sightseeing, or wildlife approaches where wake discipline matters. Some MG-514B configurations also support live PTO to drive hydraulic pumps for deck gear; when planning a replacement, verify that your rebuild supports the same PTO drive (speed, spline, and torque) as your existing setup.

Applications & Use-Case Matching for MG-514B

Planing Utility & Patrol Craft (2.00:1, 3.00:1)

Fast utility boats need crisp engagement, predictable docking behavior, and acceleration that keeps the bow light. The shallow-case MG-514B in 2:1 or 3:1 serves these needs cleanly: higher shaft RPM gives smaller props the authority they need to grab water quickly. Many pilots and crew boats favor 3:1 for better backing power and a quieter wheel at cruise.

Displacement & Semi-Displacement Workboats (4.00:1 to 6.00:1)

Tugs, trawlers, push boats, and heavy tour vessels benefit from deep-case MG-514B ratios. The slower, stronger shaft turns a larger wheel with more blade area, reducing cavitation and delivering confident thrust in reverse. If your job involves spending long hours nudging barges or running gear, 4.5:1 to 6:1 is where your operational comfort lives.

Passenger & Tour Operations (3.00:1 to 4.50:1 with Trolling Valve)

Passenger comfort rides on low vibration and smooth low-speed control. Pairing a mid to mid-high ratio with a trolling valve allows the captain to trim prop slip for whisper-quiet harbor transits and precise pier work. That combination keeps operators and guests happy while lowering fatigue on crew.

Choosing the Right Rebuilt MG-514B

Match Ratio to Prop & Route

If your current propeller and engine are staying put, replacing your MG-514B with the same ratio and case depth is the safest path. If you’re solving a performance issue—say, sluggish acceleration, cavitation in chop, or poor backing authority—use the ratio guide above as a north star and get a prop curve from your propeller shop. The goal is a working WOT that falls inside the engine maker’s spec while delivering the thrust profile your routes demand.

Confirm Case Depth Before You Buy

Moving from shallow to deep (or vice versa) without planning for output centerline changes can force unplanned shaft or stringer work. Unless you’re already modifying the driveline, maintain your original case style.

Rotation, Controls & PTO

Document current shaft rotation, control type (mechanical/hydraulic), and any PTO needs before ordering. A five-minute survey at the boat saves hours of phone calls later.

Budgeting the Exchange

Exchange pricing with a refundable core deposit keeps upfront cost predictable. Build your budget with freight, a set of new cooler hoses, gear oil, and if needed, the MG-514 ring drive (SAE #1). For most operators, the total cost of a well-planned change-out is far less than carrying a boat out of service for unexpected diagnostics later.

MG-514 Ring Drive (SAE #1) — Purpose & Best Practices

What the Ring Drive Does

The ring drive (sometimes called a drive gear or drive plate gear) is the precision interface that transfers engine torque through the bellhousing to the transmission input. On MG-514B installations with an SAE #1 housing, it’s the foundational link in the power path; if the teeth are worn or the mounting face is damaged, you invite vibration, chatter, and premature wear.

When to Replace

-

Tooth flanks show pitting, spalling, or uneven polishing

-

Evidence of heat checking or bluing from slippage

-

Bolt holes elongated or fretting marks on the mounting face

-

Audible whine that tracks with prop load and not engine RPM alone

Replacing the ring drive during a gearbox swap is inexpensive insurance; you’re already aligned on the bellhousing, so it’s the natural moment to renew.

Fitment & Stock

The MG-514 ring drive listed here is sized for SAE #1 housings, covering MG-514B and MG-514C applications that share that interface. Keeping one in spares alongside cooler gaskets and control cables is smart practice for remote operations.

Ordering, Shipping & Turnaround

In-Stock Availability

The rebuilt MG-514B ratios listed here are maintained in stock so working vessels can minimize downtime. Availability is flagged live on each item. If your boatyard slot is booked, order ahead and have the crate waiting on the dock the morning pull-out starts.

Crating & Freight

Transmissions ship in purpose-built crates designed for forklift handling and weather exposure during transit. The same crate returns your core—keep the foam blocks, bolts, and strap hardware when you unbox the rebuilt unit so the return takes ten minutes, not an afternoon.

Core Return Checklist

-

Drain oil to shipping safe levels

-

Cap or plug all ports to prevent leaks

-

Secure output coupling to prevent movement

-

Include the bellhousing adapter if it was part of the original assembly

-

Photograph the core in the crate before sealing (helps speed your refund)

Once the core passes basic inspection for completeness and rebuildability, the deposit is refunded using your original payment method.

Warranty & Support

Rebuilt MG-514B units include a warranty backed by a team that knows commercial duty cycles. If you have questions about oil coolers, control valves, or rotation matching, support can walk through the specifics so you get on-water outcomes—not hold music.

Why Buy Your Rebuilt Twin Disc MG-514B from Diesel Pro Power

Spin-Tested Reliability

Every MG-514B is spin-tested prior to shipment. That means clutch engagement, hydraulic pressure, and temperature behavior are verified on a test stand so you receive a gearbox that performs as advertised the first time you shift.

Purpose-Built Commercial Inventory

From 2.00:1 shallow case to 6.00:1 deep case, the ratios here reflect what real operators run. Whether you’re pushing, pulling, patrolling, or carrying passengers, you can match your existing spec precisely or step to a better-suited ratio with confidence.

SAE #1 Ring Drive On the Same Shelf

Pairing a rebuilt gear with a fresh MG-514 SAE #1 ring drive is straightforward—no second vendor, no hunting for compatibility notes. One cart, one shipment, one point of accountability.

Fast, Global Shipping & Straightforward Core Refunds

Commercial boats can’t sit idle. With in-stock units and streamlined core returns, Diesel Pro Power keeps the calendar on your side. You’ll know what ships when, how the core is evaluated, and when to expect your refund—no surprises.

40,000+ Satisfied Customers

A large, repeat customer base is built on predictable outcomes. The combination of vetted rebuilds, real-world ratio coverage, and responsive support keeps fleets returning season after season.

Multilingual, Commercial-Savvy Support

From English to Spanish, the team understands the vocabulary of shipyards and wheelhouses—whether you call it an “anillo para el drive” or a ring drive, you’ll get accurate, actionable answers.

Practical Buying Scenarios (MG-514B)

Like-for-Like Replacement

Your data plate reads MG-514B, 3.00:1, shallow case. You want the fastest path to sea trials. Order the 3.00:1 shallow case rebuilt unit, add the SAE #1 ring drive if your current one shows wear, and reuse existing cooler and controls after inspection. Your alignment targets and shaft rotation remain unchanged.

More Push for a Heavier Mission

You re-rigged for heavier traps and the boat feels labored backing into current. Moving from 3.00:1 shallow case to 4.00:1 deep case yields more torque and calmer prop noise. Check output centerline differences and stringer height in planning—your yard will advise whether the swap is bolt-in or needs shimming.

Passenger Comfort & Wake Discipline

You operate tours in sensitive habitat. Pair 4.50:1 deep case with a trolling valve so the wheel turns slower at idle without stalling the engine. Dock approaches become whisper-quiet, and the helm gains fine-grain control for wildlife passes.

High-Thrust Harbor Work

For pushboat duty and tight maneuvering, the 5.00:1 or 6.00:1 deep case MG-514B provides serious backing authority and throttle-friendly torque. These ratios reduce cavitation and deliver predictable bite when you need to arrest momentum quickly.

Fitment Checklist Before You Click “Add to Cart”

Data Plate Information

Capture the existing transmission’s model (MG-514B), ratio, case depth (shallow or deep), and serial. If the plate is missing, measure the case depth and confirm ratio from service records.

Shaft Rotation

Verify which way each prop turns when the engine is in ahead. Match the gearbox build to preserve handling characteristics, especially on twin-screw boats where counter-rotation matters.

Controls & Trolling

Note whether your helm uses mechanical or hydraulic actuation and whether you require a trolling valve. Ordering the correct build the first time speeds commissioning.

Cooling Circuit

Identify whether your cooler is seawater or jacket-water fed, and inspect hose condition. A fresh set of hoses during a gearbox swap is cheap insurance against leaks.

Ring Drive Condition (SAE #1)

Inspect teeth for pitting or chips and the mounting face for fretting. If in doubt, add the MG-514 ring drive (SAE #1) to the order. It’s easier to do now than later.

MG-514B Rebuilt Units — Summary of Options in This Section

-

MG-514B 2.00:1 — Shallow Case — Rebuilt

Exchange sale with refundable core deposit. Spin-tested, ready for light to mid-duty planing craft needing crisp response. -

MG-514B 3.00:1 — Shallow Case — Rebuilt

Exchange sale with refundable core deposit. A versatile commercial favorite balancing push and cruise efficiency. -

MG-514B 4.00:1 — Deep Case — Rebuilt

Exchange sale with refundable core deposit. First stop for displacement and semi-displacement vessels requiring more bite. -

MG-514B 4.50:1 — Deep Case — Rebuilt

Exchange sale with refundable core deposit. Strong low-speed authority without over-slowing transit legs. -

MG-514B 5.00:1 — Deep Case — Rebuilt

Exchange sale with refundable core deposit. Heavy-haul confidence for tugs, trawlers, and pushers. -

MG-514B 6.00:1 — Deep Case — Rebuilt

Exchange sale with refundable core deposit. Maximum torque multiplication and precise maneuvering at controlled shaft RPM. -

MG-514 Ring Drive — Housing Size SAE #1

Stocked accessory for MG-514B/514C installations using SAE #1. Replace on condition to prevent vibration and extend service life.

After-Sale Confidence

Rebuilt MG-514B transmissions from Diesel Pro Power are supported by people who speak the same language as your yard and wheelhouse. If you need ratio guidance, rotation confirmation, or help matching a ring drive, you’ll get concise, practical answers. And because the units are maintained in stock, you can plan the change-out around tides, weather, and your charter calendar—not lead times.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588