Introduction to the Caterpillar 3400 Series

The Caterpillar 3400 Series represents some of the most widely used heavy-duty diesel engines in the marine and industrial sectors. These engines are built for demanding environments and serve in fishing vessels, tugboats, generator sets, drilling rigs, offshore platforms, and large-scale construction equipment.

Originally introduced as mechanically governed engines, the 3400 Series evolved into electronically controlled platforms that offer improved fuel efficiency, diagnostics, and emissions performance. These changes are reflected in the transition from the original models to the B, C, and E designations.

The continued relevance of these engines, despite newer model introductions, is due in part to the robust availability of high-quality aftermarket parts. Proper maintenance and access to reliable parts can extend the operational life of these engines well past their original design expectations.

Key Features of the 3400 Series Engine Family

All engines in the 3400 Series share core Caterpillar values: power, reliability, and ease of rebuild. However, the design differences between models reflect their intended applications and technological evolution.

Caterpillar 3406

- Configuration: Inline 6-cylinder

- Displacement: 14.6 liters

- Power Range: 300–550 HP (depending on variant)

- Applications: Marine propulsion, power generation, construction equipment, and oilfield machinery

- Models: 3406, 3406B, 3406C, 3406E

Caterpillar 3408

- Configuration: V8

- Displacement: 18.0 liters

- Power Range: 400–600 HP

- Applications: Tugboats, dredging systems, offshore pumping systems, and marine propulsion

- Models: 3408, 3408B, 3408C, 3408E

Caterpillar 3412

- Configuration: V12

- Displacement: 27.0 liters

- Power Range: 550–900 HP

- Applications: Large marine vessels, generators, jack-up rigs, and industrial pumping

- Models: 3412, 3412B, 3412C, 3412E

Differences Between Original, B, C, and E Models

Understanding model evolution is critical for ordering the correct aftermarket parts.

Base Models

The original 3406, 3408, and 3412 were mechanical engines. Simpler to maintain, they relied on mechanical fuel pumps and analog gauges. These engines are still in use, particularly in remote operations where simplicity is an asset.

B Models

The B models introduced refinements in fuel injection and mechanical reliability. Though still mechanical, they featured stronger block castings, improved cooling paths, and better serviceability.

C Models

The C models continued mechanical governance but optimized thermal performance, airflow, and gasket sealing. These engines served as a transitional phase, preparing for electronic controls.

E Models

The E series introduced full electronic controls, including ECMs (Electronic Control Modules), diagnostic ports, and electronically actuated fuel systems. They offer higher fuel efficiency, emissions control, and onboard diagnostics. The E Series engines require electronic-compatible components and software interfaces.

Common Aftermarket Components

For each model in the 3400 Series, aftermarket parts can be categorized into core systems. Below are the critical parts groups, their function, and what to consider when sourcing them. Each model listed under a category is labeled to match the corresponding component type for clear hyperlinking.

Engine Overhaul Kits

These kits include pistons, liners, rings, connecting rod bearings, main bearings, thrust washers, and gaskets. They’re ideal for full rebuilds and are available in both standard and oversize measurements.

Key Considerations:

- Verify compression ratios by model

- Check piston crown shape (especially for turbocharged vs. naturally aspirated engines)

- Match kit specifications to engine serial number and arrangement number

Applicable Models:

- 3406 overhaul kits

- 3406B overhaul kits

- 3406C overhaul kits

- 3406E overhaul kits

- 3408 overhaul kits

- 3408B overhaul kits

- 3408C overhaul kits

- 3412 overhaul kits

- 3412B overhaul kits

- 3412C overhaul kits

- 3412E overhaul kits

Cylinder Heads

Remanufactured or new cylinder heads ensure proper combustion and compression. They are typically supplied fully assembled with valves, seats, and springs.

Key Considerations:

- Confirm compatibility with either mechanical or electronic valve actuation

- Use marine-grade materials when used in corrosive environments

Applicable Models:

- 3406 cylinder heads

- 3406B cylinder heads

- 3406C cylinder heads

- 3406E cylinder heads

- 3408 cylinder heads

- 3408B cylinder heads

- 3408C cylinder heads

- 3412 cylinder heads

- 3412B cylinder heads

- 3412C cylinder heads

- 3412E cylinder heads

Turbochargers

The 3400 Series engines can be single- or twin-turbocharged, depending on the application. Turbo upgrades can restore lost power or improve boost pressures.

Key Considerations:

- Marine turbos should use corrosion-resistant housings

- Match turbo model number stamped on original housing

- Verify whether twin-scroll or single-scroll configurations are required

Applicable Models:

- 3406 turbochargers

- 3406B turbochargers

- 3406C turbochargers

- 3406E turbochargers

- 3408 turbochargers

- 3408B turbochargers

- 3408C turbochargers

- 3412 turbochargers

- 3412B turbochargers

- 3412C turbochargers

- 3412E turbochargers

Fuel System Components

These include fuel injectors, fuel pumps (mechanical or electronic), injector sleeves, and fuel lines.

Key Considerations:

- Use marine-rated fuel injectors in high-moisture environments

- Confirm ECM compatibility on electronically controlled engines

- Match nozzle spray angle and pressure rating to application

Applicable Models:

- 3406 fuel system components

- 3406B fuel system components

- 3406C fuel system components

- 3406E fuel system components

- 3408 fuel system components

- 3408B fuel system components

- 3408C fuel system components

- 3412 fuel system components

- 3412B fuel system components

- 3412C fuel system components

- 3412E fuel system components

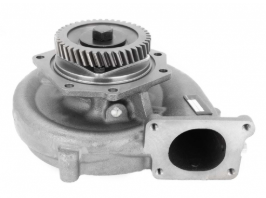

Cooling System Components

These include water pumps (freshwater and raw water), thermostats, heat exchangers, and hoses.

Key Considerations:

- Use stainless steel and bronze components for marine applications

- Verify heat exchanger capacity based on engine rating and ambient temperature

- Double-check gasket materials for saltwater resistance

Applicable Models:

- 3406 cooling system components

- 3406B cooling system components

- 3406C cooling system components

- 3406E cooling system components

- 3408 cooling system components

- 3408B cooling system components

- 3408C cooling system components

- 3412 cooling system components

- 3412B cooling system components

- 3412C cooling system components

- 3412E cooling system components

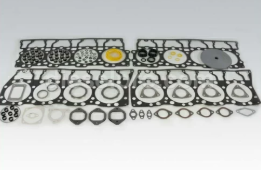

Gasket and Seal Sets

Gasket kits are essential for top-end rebuilds, full overhauls, and sealing oil and coolant passages.

Key Considerations:

- Marine gaskets often require special coating to resist saltwater

- Use heat-rated gasket materials for turbocharger flanges

- Ensure kits are matched by engine serial number

Applicable Models:

- 3406 gasket sets

- 3406B gasket sets

- 3406C gasket sets

- 3406E gasket sets

- 3408 gasket sets

- 3408B gasket sets

- 3408C gasket sets

- 3412 gasket sets

- 3412B gasket sets

- 3412C gasket sets

- 3412E gasket sets

Oil Pumps and Lubrication Parts

Oil pumps, pressure relief valves, filters, and coolers ensure consistent lubrication. A failed oil system can lead to catastrophic engine failure.

Key Considerations:

- Flow rate should match OEM specifications

- Use high-capacity oil coolers in heavy-load or hot climate operations

- Always prime oil pump after installation

Applicable Models:

- 3406 oil pump components

- 3406B oil pump components

- 3406C oil pump components

- 3406E oil pump components

- 3408 oil pump components

- 3408B oil pump components

- 3408C oil pump components

- 3412 oil pump components

- 3412B oil pump components

- 3412C oil pump components

- 3412E oil pump components

Electrical and Sensor Systems

This includes ECMs, wiring harnesses, temperature sensors, oil pressure sensors, and turbo boost sensors—especially on E-models.

Key Considerations:

- Avoid universal sensors unless they meet Caterpillar voltage thresholds

- Marine applications should use waterproof harnesses

- ECMs must match the engine’s flash file and calibration

Applicable Models:

- 3406E electrical and sensor components

- 3408E electrical and sensor components

- 3412E electrical and sensor components

Note: Electrical parts for pre-E models are minimal and generally limited to basic senders, starters, and alternators.

Unique Marine and Industrial Considerations

Marine Environments

- Corrosion Resistance: All parts exposed to salt water must be marine-rated (brass, stainless, anodized).

- Vibration Control: Use reinforced mounts and bushings.

- Remote Monitoring: Marine vessels often require sensor redundancy for safety.

- Cooling Systems: Dual-loop systems are common—ensure proper selection of heat exchangers.

Industrial Environments

- Dust and Debris: Install upgraded filtration for air and oil.

- Temperature Extremes: Use coolant with appropriate freeze or boil point additives.

- Continuous Operation: Choose heavy-duty rated bearings and valve train components for engines running 24/7.

- High Altitude Applications: Fuel delivery and turbo sizing may need adjustment.

Serial Nu

mber Reference for Parts Matching

It’s critical to reference the engine’s full serial number and arrangement number when ordering aftermarket parts. Caterpillar engines often vary internally even within the same model group. Example differences include:

- Compression ratios

- Piston bowl designs

- Fuel map calibrations

- Turbocharger frame sizes

- Gasket thicknesses

Never rely solely on the engine model (e.g., 3406E) without confirming serial-based configurations.

Sourcing Reliable Aftermarket Parts

Choosing a trustworthy aftermarket supplier is just as important as selecting the right component. At Diesel Pro Power, our aftermarket parts are carefully selected to support long-term engine reliability for marine and industrial customers worldwide.

Warranty

Diesel Pro Power backs its aftermarket parts with a solid one-year warranty. This warranty protects against manufacturing defects and early part failure, giving our customers peace of mind when rebuilding or maintaining their Caterpillar 3400 Series engines.

OEM Match Quality

Our parts are sourced to match OEM specifications in fit and function—often with improvements in materials or corrosion resistance for marine applications. While we do not perform ISO certification or dyno testing, we thoroughly vet our suppliers to ensure consistent performance, durability, and compatibility.

Why customers trust our quality:

- Consistent product tolerances

- Corrosion-resistant coatings for marine environments

- Parts matched to serial and arrangement numbers

- Proven performance in thousands of installations

Technical Support and Expertise

At Diesel Pro Power, you’re never alone when selecting parts. Our support team offers real-time help to minimize downtime and ensure accuracy. We provide:

- Live technical assistance

- Guidance on serial number decoding

- Model-specific compatibility advice

Whether you’re ordering a full rebuild kit or a replacement sensor, our knowledgeable staff ensures you get the right part—fast. This level of personalized support is one reason why thousands of marine mechanics and industrial operators choose Diesel Pro Power as their trusted aftermarket source.

Maintenance Best Practices

Using aftermarket parts is only half the battle. Maintenance practices dictate long-term performance.

Fluid Analysis

Regular oil and coolant sampling can detect early signs of engine wear or contamination. This protects your investment in new parts and helps schedule proactive maintenance.

Break-In Procedures

Engines with new pistons or heads require controlled break-in:

- Avoid high RPM for the first 20 hours

- Use break-in oil if specified

- Monitor oil pressure and exhaust temperature closely

Scheduled Inspections

For marine applications, inspect raw water impellers, heat exchangers, and exhaust elbows regularly for blockages and corrosion. Industrial engines should be inspected for dust ingress, fuel quality, and crankcase pressure.

Rebuild vs. Replacement Strategy

Deciding between a full rebuild using aftermarket parts or replacing the engine depends on several factors:

- Engine block condition: Cracks or excessive liner wear may make rebuilding unviable.

- Part availability: If key internal parts are unavailable or backordered, consider reman engines.

- Downtime: If equipment must run 24/7, drop-in replacements may offer faster turnaround.

- Cost per hour: Rebuilds often cost less long-term but require skilled labor and downtime.

FAQs About Caterpillar 3400 Series Aftermarket Parts

Are aftermarket parts as good as OEM parts?

Yes, many high-quality aftermarket parts meet or exceed OEM specifications, especially when sourced from reputable suppliers.

Can I mix mechanical and electronic parts on the same engine?

Not typically. Electronic engines require ECM-compatible sensors and fuel systems. Mixing components can cause performance issues or failure.

How do I find my engine’s serial number?

Look for a stamped metal tag on the valve cover or the engine block. For marine engines, it may be mounted on the transmission bell housing.

Do marine parts differ from industrial ones?

Yes. Marine parts are corrosion-resistant and optimized for saltwater cooling and vibration. Always specify your application when ordering.

What is the difference between standard and oversize parts in rebuild kits?

Oversize parts accommodate worn engine bores and journals. Micrometer measurements are needed to confirm sizing.

Conclusion

The Caterpillar 3400 Series—spanning the 3406, 3408, and 3412 engines in their base, B, C, and E forms—continues to serve the global marine and industrial markets with unwavering dependability. Thanks to the robust availability of premium aftermarket parts, operators can extend the life of these engines without relying on OEM-only supply chains.

By understanding model evolution, sourcing the right components, and adhering to best practices for maintenance, businesses can reduce operating costs and avoid unplanned downtime.

Whether you’re repowering a tugboat, overhauling a drilling rig engine, or maintaining a generator fleet, investing in quality aftermarket parts for the 3400 Series pays off in performance, durability, and value.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588