Overview of Engine Design and Performance

The Cummins ISB (Interact System B) and QSB (Quantum System B) engines are part of Cummins’ renowned B-Series family, which has been celebrated for decades due to its durability, fuel efficiency, and performance versatility. These engines are engineered to deliver outstanding reliability and power across diverse applications, from marine environments to industrial equipment, trucking, and agricultural machinery.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Cummins QSB 6.7 & Related Components

Cummins QSB 7.0 & Related Components

1. Engine Block and Structural Design

The ISB and QSB engines share several structural design features that contribute to their robust performance and longevity:

- Material: Both engines are constructed using a cast-iron block, known for its strength and resistance to wear and tear. This material choice ensures the engines can handle high stress and extreme temperatures without compromising durability.

- Cylinder Liners: They may feature either wet or dry cylinder liners, depending on the specific engine variant. Wet liners are in direct contact with the coolant, improving heat dissipation, while dry liners offer simpler replacement procedures.

- Crankshaft Design: A forged steel crankshaft adds to the overall durability of these engines, supporting higher loads without deformation over time.

Crankshaft & Related Components for Cummins ISB 4.5 Engine

Crankshaft & Related Components for Cummins ISB 5.9 Engine

Crankshaft & Related Components for Cummins ISB 6.7 Engine

Crankshaft & Related Components for Cummins QSB 4.5 Engine

Crankshaft & Related Components for Cummins QSB 5.9 Engine

Crankshaft & Related Components for Cummins QSB 6.7 Engine

Crankshaft & Related Components for Cummins QSB 7.0 Engine

2. Displacement Variants

Cummins ISB and QSB engines come in several displacement sizes, providing flexibility for different operational needs:

- 4.5L: Compact and efficient, commonly used in smaller industrial machinery, light-duty trucks, and compact marine applications.

- 5.9L: A versatile size, known for its balance of power and fuel efficiency. Found in mid-sized trucks, agricultural equipment, and marine vessels.

- 6.7L: The most powerful variant within the series, designed for heavy-duty applications such as commercial trucks, large industrial equipment, and marine vessels requiring high torque and horsepower.

Each displacement offers different power outputs, torque ratings, and fuel efficiency profiles, allowing operators to choose the best engine based on their specific needs.

Piston Kit & Related Components for Cummins ISB 4.5 Engine

Piston Kit & Related Components for Cummins ISB 5.9 Engine

Piston Kit & Related Components for Cummins ISB 6.7 Engine

Piston Kit & Related Components for Cummins QSB 4.5 Engine

Piston Kit & Related Components for Cummins QSB 5.9 Engine

Piston Kit & Related Components for Cummins QSB 6.7 Engine

Piston Kit & Related Components for Cummins QSB 7.0 Engine

3. Fuel System Technology

One of the most critical components of the ISB and QSB engines is the high-pressure common rail (HPCR) fuel system. This advanced fuel injection system delivers several key benefits:

- Precise Fuel Delivery: The HPCR system allows for precise control over fuel injection timing and quantity, optimizing combustion for maximum efficiency and reduced emissions.

- Improved Fuel Economy: By atomizing fuel more effectively, the system improves combustion efficiency, leading to lower fuel consumption.

- Reduced Noise: Better fuel atomization also contributes to quieter engine operation, especially at idle and low speeds.

Injector & Related Components for Cummins ISB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins ISB 5.9 Engine

Injector & Related Components for Cummins ISB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins QSB 5.9 Engine

Injector & Fuel Pump Related Components for Cummins QSB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 7.0 Engine

4. Electronic Control Module (ECM)

Modern Cummins ISB and QSB engines feature advanced Electronic Control Modules (ECMs), which act as the brain of the engine:

- Real-Time Monitoring: The ECM continuously monitors key parameters such as fuel injection timing, air intake pressure, exhaust gas recirculation (EGR) rates, and coolant temperatures.

- Optimized Performance: By adjusting these variables in real-time, the ECM ensures the engine operates at peak efficiency under various load conditions.

- Diagnostic Capabilities: The ECM can store fault codes and diagnostic data, making it easier for technicians to identify and troubleshoot issues quickly.

5. Turbocharging Systems

Both ISB and QSB engines are turbocharged, with some models featuring variable geometry turbochargers (VGTs):

- Enhanced Power Output: Turbocharging increases the amount of air entering the combustion chamber, allowing for more fuel to be burned and, consequently, greater power output.

- Fuel Efficiency: Turbochargers improve engine efficiency by recovering energy from the exhaust gases that would otherwise be wasted.

- Wastegate Control: Some models use a wastegate system to regulate boost pressure, preventing over-boost conditions and protecting the engine.

Turbocharger & Related Components for Cummins ISB 4.5 Engine

Turbocharger & Related Components for Cummins ISB 5.9 Engine

Turbocharger & Related Components for Cummins ISB 6.7 Engine

Turbocharger & Related Components for Cummins QSB 4.5 Engine

Turbocharger & Related Components for Cummins QSB 5.9 Engine

Turbocharger & Related Components for Cummins QSB 6.7 Engine

Turbocharger & Related Components for Cummins QSB 7.0 Engine

6. Emissions Control Technologies

To comply with stringent emissions regulations worldwide, ISB and QSB engines incorporate advanced emissions control technologies:

- Exhaust Gas Recirculation (EGR): Reduces nitrogen oxide (NOx) emissions by recirculating a portion of the exhaust gases back into the intake manifold, lowering combustion temperatures.

- Diesel Particulate Filter (DPF): Captures soot particles from the exhaust, reducing particulate matter emissions.

- Selective Catalytic Reduction (SCR): Uses a urea-based solution to convert NOx into harmless nitrogen and water vapor, meeting EPA Tier 4 and Euro V/V standards.

7. Cooling Systems

Efficient cooling is vital for maintaining optimal engine performance:

- Liquid Cooling System: Both engines utilize a liquid-cooled system with high-capacity water pumps, ensuring even temperature distribution across all engine components.

- Heat Exchangers (Marine Versions): In marine applications, heat exchangers are often used instead of traditional radiators, utilizing seawater to cool the engine coolant.

Freshwater Pump & Related Components for Cummins ISB 4.5 Engine

Freshwater Pump & Related Components for Cummins ISB 5.9 Engine

Freshwater Pump & Related Components for Cummins ISB 6.7 Engine

Freshwater Pump & Related Components for Cummins QSB 4.5 Engine

Freshwater Pump & Related Components for Cummins QSB 5.9 Engine

Freshwater Pump & Related Components for Cummins QSB 6.7 Engine

Freshwater Pump & Related Components for Cummins QSB 7.0 Engine

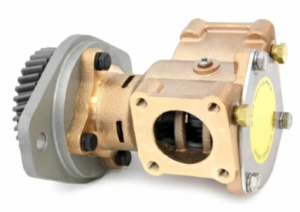

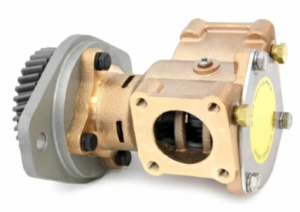

Raw Water Pump & Related Components for Cummins QSB 5.9 Engine

Raw Water Pump & Related Components for Cummins QSB 6.7 Engine

Raw Water Pump & Related Components for Cummins QSB 7.0 Engine

8. Lubrication System

A robust lubrication system ensures that all moving parts are properly lubricated, reducing friction and wear:

- Full-Flow Oil Filtration: Ensures that contaminants are removed from the oil before it circulates through the engine.

- Bypass Oil Filters: Provide additional filtration for extended maintenance intervals.

Lubrication System & Related Components for Cummins ISB 4.5 Engine

Lubrication System & Related Components for Cummins ISB 5.9 Engine

Lubrication System & Related Components for Cummins ISB 6.7 Engine

Lubrication System & Related Components for Cummins QSB 4.5 Engine

Lubrication System & Related Components for Cummins QSB 5.9 Engine

Lubrication System & Related Components for Cummins QSB 6.7 Engine

Lubrication System & Related Components for Cummins QSB 7.0 Engine

Applications in Various Industries

The versatility of the Cummins ISB and QSB engines is one of their standout features. They are designed to meet the demands of a wide range of industries, each with unique operational requirements.

1. Marine Industry

Cummins ISB and QSB engines are widely used in marine applications, where reliability and performance are critical. These engines are found in:

- Commercial Fishing Vessels: The engines’ high torque at low RPMs is perfect for vessels that require consistent pulling power for trawling and hauling nets.

- Recreational Yachts: Their quiet operation, fuel efficiency, and compact size make them ideal for luxury yachts.

- Workboats and Tugboats: The robust construction and durability ensure reliable performance in demanding marine environments, including tugboats and pilot vessels.

- Patrol Boats and Rescue Vessels: The quick throttle response provided by the electronic fuel system is vital in emergency situations.

Marine-Specific Features:

- Corrosion-Resistant Components: Protect against saltwater damage.

- Marine-Specific Cooling Systems: Including keel cooling and heat exchangers for optimal performance.

2. Industrial Applications

In the industrial sector, Cummins ISB and QSB engines power a variety of equipment that operates under harsh conditions:

- Generators: Providing reliable backup and primary power for hospitals, construction sites, and remote operations.

- Cranes and Material Handlers: The high torque output is crucial for lifting heavy loads.

- Mining Equipment: Designed to withstand extreme conditions, including dust, moisture, and temperature fluctuations.

- Oil and Gas Industry: Used in drilling rigs, pumps, and compressors, where continuous-duty operation is required.

Industrial-Specific Benefits:

- Continuous Duty Performance: Engines are designed to run 24/7 without compromising reliability.

- Low Maintenance Costs: Simplified engine design for easy access during servicing.

3. Trucking and Transportation

Cummins ISB engines are a mainstay in the trucking industry, particularly for medium-duty and heavy-duty trucks:

- Long-Haul Trucks: Known for fuel efficiency and long service intervals, making them cost-effective for fleet operators.

- Delivery Vehicles: The compact design allows for easy integration into urban delivery trucks where space is limited.

- Public Transit and School Buses: The quiet operation and low emissions meet stringent city regulations while providing reliable performance.

Transportation-Specific Features:

- Advanced ECM Programming: Optimizes performance for different driving conditions.

- Extended Service Intervals: Reduces downtime and operating costs.

4. Agricultural Equipment

In the agriculture industry, Cummins ISB and QSB engines are used in equipment such as:

- Tractors: Providing the torque needed for heavy pulling tasks.

- Harvesters: Ensuring consistent power output during demanding operations.

- Irrigation Pumps: Reliable performance for critical water management systems.

- Agricultural-Specific Advantages:

- High Torque at Low RPMs: Ideal for heavy-duty tasks.

- Fuel Efficiency: Reduces operational costs for large-scale farms.

5. Construction Equipment

The construction industry demands engines that can withstand tough environments:

- Excavators and Loaders: The power-to-weight ratio ensures efficient digging and lifting capabilities.

- Bulldozers: Provide consistent power output for moving large volumes of earth and debris.

- Concrete Mixers: The torque curve of these engines ensures the mixer operates efficiently, even under heavy loads.

Construction-Specific Features:

- Dust-Resistant Design: Protects critical components from environmental damage.

- Easy Maintenance Access: Reduces downtime on job sites.

Why Choose Cummins ISB and QSB Engines?

- Versatility: Suitable for marine, industrial, trucking, agricultural, and construction applications.

- Reliability: Built to last with durable materials and advanced engineering.

- Fuel Efficiency: Designed to deliver maximum power while minimizing fuel consumption.

- Environmental Compliance: Meets global emissions standards without compromising performance.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588