Please note that these are typical maintenance intervals for the Marine Cummins QSB engine, and some results may vary based on operating conditions. Adhering to these schedules is essential for ensuring reliable performance and extending the engine’s operational life.

Marine Cummins QSB 4.5 Component Maintenance Life

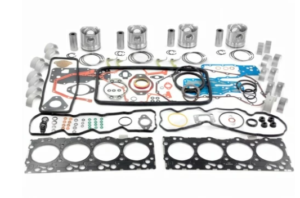

Rebuild Kit for Cummins QSB 4.5 – 1 piece piston

Component

Maintenance Interval (Hours)

Notes

Oil and Filter Change 250 hours Regular oil changes are crucial for maintaining engine lubrication and preventing wear.

Fuel Filters 500 hours Replace to ensure clean fuel and prevent injector clogging.

Air Filters 500 hours Inspect regularly; replace if dirty to protect engine performance.

Coolant 1,000 hours Change coolant to prevent overheating and corrosion in the cooling system.

Injectors 2,000 hours Inspect, clean, or replace to maintain efficient fuel combustion.

Valve Adjustment 1,500 hours Regular adjustments ensure proper engine timing and optimal performance.

Turbocharger Inspection 2,000-3,000 hours Inspect for wear; service or replace as needed to maintain boost pressure.

Cylinder Head Overhaul 4,000-5,000 hours Overhaul includes checking for wear, cracks, and ensuring proper sealing.

Piston Rings 6,000 hours Replace during major service intervals to maintain compression.

Crankshaft Bearings 6,000-8,000 hours Inspect during overhauls; replace if signs of wear are evident.

Complete Engine Overhaul 10,000-12,000 hours A comprehensive overhaul including pistons, liners, bearings, and other major components.

Marine Cummins QSB 4.5 Coolant System Specific Component Maintenance Life Fresh Water Pump for Cummins B series engines

Component

Maintenance Interval (Hours)

Notes

Coolant 1,000 hours Change to maintain optimal cooling and prevent corrosion in the system.

Freshwater Pump 2,000-3,000 hours Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary.

Raw Water Pump 500-1,000 hours Inspect impeller for wear; replace impeller and seals as needed to maintain proper cooling.

Thermostats 1,500-2,000 hours Inspect and test; replace if malfunctioning or during major coolant system service.

Marine Cummins QSB 5.9 Component Maintenance Life One piece pistons. This kit is designed to service QSB5.9 engines

Component

Maintenance Interval (Hours)

Notes

Oil and Filter Change 250 hours Regular oil changes are crucial for maintaining engine lubrication and preventing wear.

Fuel Filters 500 hours Replace to ensure clean fuel and prevent injector clogging.

Air Filters 500 hours Inspect regularly; replace if dirty to protect engine performance.

Coolant 1,000 hours Change coolant to prevent overheating and corrosion in the cooling system.

Injectors 2,000 hours Inspect, clean, or replace to maintain efficient fuel combustion.

Valve Adjustment 1,500 hours Regular adjustments ensure proper engine timing and optimal performance.

Turbocharger Inspection 2,000-3,000 hours Inspect for wear; service or replace as needed to maintain boost pressure.

Cylinder Head Overhaul 4,000-5,000 hours Overhaul includes checking for wear, cracks, and ensuring proper sealing.

Piston Rings 6,000 hours Replace during major service intervals to maintain compression.

Crankshaft Bearings 6,000-8,000 hours Inspect during overhauls; replace if signs of wear are evident.

Complete Engine Overhaul 10,000-12,000 hours A comprehensive overhaul including pistons, liners, bearings, and other major components.

Marine Cummins QSB 5.9 Coolant System Specific Component Maintenance Life Fresh Water Pump for Cummins B series engines Raw Water Pump For Cummins QSB 5.9

Component

Maintenance Interval (Hours)

Notes

Coolant 1,000 hours Change to maintain optimal cooling and prevent corrosion in the system.

Freshwater Pump 2,000-3,000 hours Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary.

Raw Water Pump 500-1,000 hours Inspect impeller for wear; replace impeller and seals as needed to maintain proper cooling.

Thermostats 1,500-2,000 hours Inspect and test; replace if malfunctioning or during major coolant system service.

Marine Cummins QSB 6.7 Component Maintenance Life

Cummins Rebuild Kit for QSB 6.7

Component

Maintenance Interval (Hours)

Notes

Oil and Filter Change 250 hours Regular oil changes are crucial for maintaining engine lubrication and preventing wear.

Fuel Filters 500 hours Replace to ensure clean fuel and prevent injector clogging.

Air Filters 500 hours Inspect regularly; replace if dirty to protect engine performance.

Coolant 1,000 hours Change coolant to prevent overheating and corrosion in the cooling system.

Injectors 2,000 hours Inspect, clean, or replace to maintain efficient fuel combustion.

Valve Adjustment 1,500 hours Regular adjustments ensure proper engine timing and optimal performance.

Turbocharger Inspection 2,000-3,000 hours Inspect for wear; service or replace as needed to maintain boost pressure.

Cylinder Head Overhaul 4,000-5,000 hours Overhaul includes checking for wear, cracks, and ensuring proper sealing.

Piston Rings 6,000 hours Replace during major service intervals to maintain compression.

Crankshaft Bearings 6,000-8,000 hours Inspect during overhauls; replace if signs of wear are evident.

Complete Engine Overhaul 10,000-12,000 hours A comprehensive overhaul including pistons, liners, bearings, and other major components.

Marine Cummins QSB 6.7 Coolant System Specific Component Maintenance Life Fresh Water Pump for Cummins B series engines Raw Water Pump For Cummins QSB 5.9

Component

Maintenance Interval (Hours)

Notes

Coolant 1,000 hours Change to maintain optimal cooling and prevent corrosion in the system.

Freshwater Pump 2,000-3,000 hours Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary.

Raw Water Pump 500-1,000 hours Inspect impeller for wear; replace impeller and seals as needed to maintain proper cooling.

Thermostats 1,500-2,000 hours Inspect and test; replace if malfunctioning or during major coolant system service.

Marine Cummins QSB 7.0 Component Maintenance Life

Rebuild Kit for Cummins QSB 7.0

Component

Maintenance Interval (Hours)

Notes

Oil and Filter Change 250 hours Regular oil changes are crucial for maintaining engine lubrication and preventing wear.

Fuel Filters 500 hours Replace to ensure clean fuel and prevent injector clogging.

Air Filters 500 hours Inspect regularly; replace if dirty to protect engine performance.

Coolant 1,000 hours Change coolant to prevent overheating and corrosion in the cooling system.

Injectors 2,000 hours Inspect, clean, or replace to maintain efficient fuel combustion.

Valve Adjustment 1,500 hours Regular adjustments ensure proper engine timing and optimal performance.

Turbocharger Inspection 2,000-3,000 hours Inspect for wear; service or replace as needed to maintain boost pressure.

Cylinder Head Overhaul 4,000-5,000 hours Overhaul includes checking for wear, cracks, and ensuring proper sealing.

Piston Rings 6,000 hours Replace during major service intervals to maintain compression.

Crankshaft Bearings 6,000-8,000 hours Inspect during overhauls; replace if signs of wear are evident.

Complete Engine Overhaul 10,000-12,000 hours A comprehensive overhaul including pistons, liners, bearings, and other major components.

Marine Cummins QSB 7.0 Coolant System Specific Component Maintenance Life Fresh Water Pump for Cummins B series engines

Raw Water Pump For Cummins QSB 7.0

Component

Maintenance Interval (Hours)

Notes

Coolant 1,000 hours Change to maintain optimal cooling and prevent corrosion in the system.

Freshwater Pump 2,000-3,000 hours Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary.

Raw Water Pump 500-1,000 hours Inspect impeller for wear; replace impeller and seals as needed to maintain proper cooling.

Thermostats 1,500-2,000 hours Inspect and test; replace if malfunctioning or during major coolant system service.

Regular maintenance according to these intervals is crucial for the reliable operation of the Cummins QSB engine, especially in demanding marine environments. Consistent servicing and inspections help extend the engine’s life and reduce the risk of unexpected failures.

Disclaimer: The most accurate data for each specific engine will always be found in the OEM service manual. The numbers provided here are estimates and can vary based on operating conditions. Factors such as inadequate cooling, lubrication, or fuel quality issues can affect other engine components, potentially altering maintenance intervals. Engine components are interconnected, so one issue can impact others, leading to different service needs. Always tailor your maintenance approach to the specific conditions in which your engine operates.

Please follow and like us:

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588